TC Type Framework Oil Seal 12*19*20*21*22*24*25*26*28*30*32*35*3*5*6*7*8*10

TC Type Framework Oil Seal 12192021222425262830323535678*10

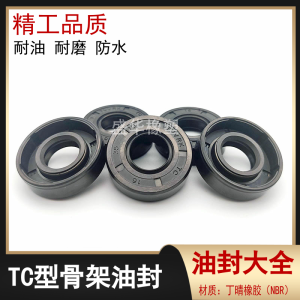

Understanding TC Type Framework Oil Seals

What is a TC Type Framework Oil Seal?

A TC Type Framework Oil Seal is a specialized component designed to prevent oil leakage from mechanical systems. These seals are commonly used in industrial machinery, such as pumps, motors, and hydraulic systems. They ensure the longevity and optimal performance of the equipment by maintaining the oil level and preventing contamination.

Key Features & Benefits

The TC Type Framework Oil Seal offers several advantages, including:

- Durability: Made from high-quality materials, these seals can withstand harsh operating conditions and extended usage.

- Compatibility: Available in various sizes, they can be easily adapted to fit different machinery types and applications.

- Cost-effective: By preventing oil leaks and reducing maintenance costs, these seals offer long-term savings.

Oil Seal Dimensions: A Comprehensive Guide

Standard Dimensions: 35678*10

Standard dimensions refer to the most common sizes used in industrial machinery. These include:

- 3mm

- 5mm

- 6mm

- 7mm

- 8mm

- 10mm

Extended Dimensions: 1219202122242526283032*35

Extended dimensions cater to larger equipment or unique applications. Some of these sizes include:

- 12mm

- 19mm

- 20mm

- 21mm

- 22mm

- 24mm

- 25mm

- 26mm

- 28mm

- 30mm

- 32mm

- 35mm

Choosing the Right Size for Your Machinery

When selecting the appropriate oil seal size, consider the following factors:

- Machinery type: Different equipment may require specific seal sizes.

- Operating conditions: Harsh environments might necessitate larger or more robust seals.

- Maintenance schedule: Regular inspections can help determine if a seal needs to be replaced or upgraded.

How to Install & Maintain TC Type Oil Seals

Step-by-Step Installation Process

Follow these steps to install a TC Type Framework Oil Seal:

- Clean the installation area thoroughly.

- Check the seal size and ensure compatibility.

- Apply a thin layer of lubricant to the seal lip.

- Insert the seal into the designated groove.

- Verify proper installation by checking for any leaks or misalignment.

Common Issues & Troubleshooting Tips

Some common issues with TC Type Framework Oil Seals include:

- Leakage: Check for proper installation and ensure the seal is compatible with the machinery.

- Damage: Inspect the seal regularly for signs of wear or damage.

- Contamination: Keep the installation area clean to prevent dirt or debris from entering the system.

Regular Maintenance for Optimal Performance

To maintain optimal performance, follow these guidelines:

- Inspect the seal regularly for signs of wear or damage.

- Replace the seal if it shows any signs of deterioration.

- Clean the installation area before and after each maintenance check.

- Follow the manufacturer's recommendations for lubrication and maintenance schedules.

TB supermarket store

Review

You May Also Like

Shockwave Live Star 44: A 300-Watt Compression Driver Unit Tweeter

10cm Truck Rope Fastener Tensioner Truck Welding Pull Rope Fastener Universal Manual Rope Tensioner

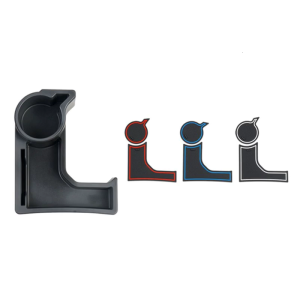

Waterproof Automatic Transmission Center Console Gear Shifter Storage Box Organizer Tray with Cup Holder for JB64W JB74W

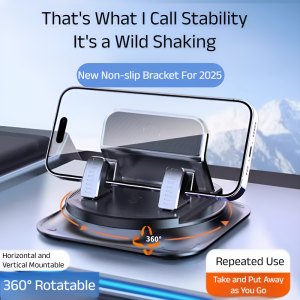

2025 Central Control Instrument Panel Car Mobile Phone Holder 360 Degree Rotating Sticky Suction Cup Car Home Navigation Support 360 度旋转仪表盘手机支架

Car trunk mat for MAZDA CX5 CX-5 SUV 2012 cargo liner carpet interior accessories cover 0611

1 Pair 10A 250V IEC Straight Cable Plug Connector - Perfect for Electric Vehicles

【Fast Shipping】 Universal 3 Jaws Bearing Puller Dismantlement Tool Half Shaft Unloader Remover Tools with 3 Hooks

![Mitsubishi Mirage G4 ( GLS / GLX ) 2012 to 2018 Combo Set garnish Cover [ Matte Black / Chrome ] ( Car Accessories )](https://img.lazcdn.com/g/ff/kf/S26b7c2ecfe624beb9c03770f8d67d683l.jpg_300x300q80.jpg)

Mitsubishi Mirage G4 ( GLS / GLX ) 2012 to 2018 Combo Set garnish Cover [ Matte Black / Chrome ] ( Car Accessories )

CPA ANDROID CAR STEREO COVER 9INCH NISSAN NAVARA 2006-2012 WITH STEREO WIRE HARNESS POWER CABLE (11492)

Headrest for Toyota hiace commuter decontent ( set 8pcs )

CPA NISSAN NAVARA NP300 2015-2022 Tail Light ABS Rear Brake Turn Signal Light 1Pair (8246)