Diamond Hand Polishing Pads: A Comprehensive Guide

Diamond Hand Polishing Pads: A Comprehensive Guide

Introduction to Diamond Hand Polishing Pads

What Are Diamond Hand Polishing Pads?

Diamond hand polishing pads are versatile tools used for achieving a smooth, polished finish on various materials such as stone, marble, ceramic, tile, glass, and abrasive grinding blocks. These pads are designed with diamond particles embedded in a durable backing, allowing them to effectively remove imperfections and create a polished surface. They come in various grit sizes, which determine the level of abrasiveness and the desired finish.

Applications of Diamond Hand Polishing Pads

Diamond hand polishing pads are widely used in the following applications:

- Polishing stone, marble, and ceramic surfaces

- Removing scratches and imperfections from glass and tile

- Creating a polished finish on abrasive grinding blocks

- Enhancing the appearance of polished surfaces

Choosing the Right Polishing Pad

Factors to Consider When Selecting a Polishing Pad

When choosing a diamond hand polishing pad, consider the following factors:

- Material being polished: Different materials may require different grit sizes and abrasiveness levels.

- Desired finish: Determine whether you want a rough, medium, or fine finish based on the application.

- Size and shape: Select a pad that fits your polisher tool and allows easy maneuverability.

- Durability: Choose a pad with a durable backing to withstand repeated use and maintain its effectiveness.

Comparing Different Types of Polishing Pads

Diamond hand polishing pads come in various types, such as:

- Single-sided pads: These have diamond particles embedded on one side only, making them ideal for specific applications.

- Double-sided pads: These have diamond particles embedded on both sides, allowing for versatility in polishing.

- Self-adhesive pads: These come with a sticky backing, making them easy to attach to polisher tools.

How to Use Diamond Hand Polishing Pads

Preparing Your Work Surface

Before using diamond hand polishing pads, prepare your work surface by:

- Cleaning the surface thoroughly to remove dirt, debris, and any loose particles.

- Ensuring the surface is flat and free of any protruding objects that may interfere with the polishing process.

- Applying a lubricant or cooling agent to prevent overheating and improve polishing efficiency.

Proper Techniques for Using Polishing Pads

To achieve optimal results when using diamond hand polishing pads, follow these techniques:

- Start with a lower grit size and gradually increase to higher grit sizes for a smoother finish.

- Apply even pressure and maintain consistent speed to avoid uneven polishing.

- Move the pad in a circular motion, overlapping strokes to ensure uniform coverage.

- Allow the surface to cool down periodically to prevent overheating and damage.

Maintaining and Cleaning Your Polishing Pads

To extend the life of your diamond hand polishing pads and ensure optimal performance, follow these maintenance tips:

- Clean the pads after each use by removing any debris or residue.

- Store the pads in a cool, dry place away from direct sunlight and moisture.

- Inspect the pads regularly for signs of wear or damage, and replace them as needed.

Understanding Polishing Discs & Tools

Overview of Polishing Discs & Tools

Polishing discs and tools are essential components in the polishing process, working together with diamond hand polishing pads to achieve a smooth, polished finish. Some common types of polishing discs and tools include:

- Polishing pads: These come in various shapes, sizes, and grit levels to accommodate different applications.

- Polishing machines: These are powered tools that rotate the polishing pad at high speeds, providing consistent pressure and coverage.

- Lubricants and coolants: These help prevent overheating and improve polishing efficiency.

Choosing the Right Tool for Your Project

When selecting a polishing tool, consider the following factors:

- Material being polished: Different materials may require different types of polishing tools.

- Desired finish: Determine whether you want a rough, medium, or fine finish based on the application.

- Ease of use: Choose a tool that is easy to handle and maneuver for optimal control.

How to Care for Polishing Discs & Tools

To extend the life of your polishing discs and tools, follow these maintenance tips:

- Clean the tools after each use by removing any debris or residue.

- Store the tools in a cool, dry place away from direct sunlight and moisture.

- Inspect the tools regularly for signs of wear or damage, and replace them as needed.

Tips for Achieving Optimal Results

Ensuring Proper Polishing Techniques

To achieve optimal results when using diamond hand polishing pads, follow these techniques:

- Start with a lower grit size and gradually increase to higher grit sizes for a smoother finish.

- Apply even pressure and maintain consistent speed to avoid uneven polishing.

- Move the pad in a circular motion, overlapping strokes to ensure uniform coverage.

- Allow the surface to cool down periodically to prevent overheating and damage.

Troubleshooting Common Issues

If you encounter issues during the polishing process, consider the following solutions:

- Uneven finish: Adjust the pressure, speed, or grit size of the polishing pad to achieve a smoother finish.

- Overheating: Apply a lubricant or coolant to prevent overheating and improve polishing efficiency.

- Damage to the surface: Inspect the surface for any protruding objects or debris that may interfere with the polishing process.

Enhancing Your Polishing Skills

To enhance your polishing skills, consider the following tips:

- Practice on scrap materials to gain experience and confidence.

- Experiment with different grit sizes and techniques to find what works best for your application.

- Attend workshops or training sessions to learn from experienced professionals.

George Global

Review

You May Also Like

Bi-Folding Sliding Barn Door Hardware Kit: A Comprehensive Guide

3mm-12mm Counterbore Milling High Speed Steel Pilots Slotting Tool End Mill Slot for Woodworking

10Pcs Self-Adhesive Cable Organizer Wire Tie Management Clips Cable Clamp Cord Wire Tie Fixer

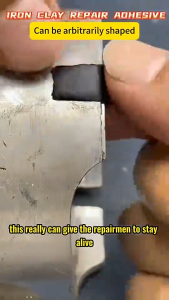

100g Multi Purpose Epoxy Compond Powerful Viscosity Mud Iron Clay Adhesive Foundry Glue Heat Resistance Metal Repair Paste For Metal Wood Glass Stone

KWS-DC26 DC8-80V Battery Charging Detector LCD Color Screen Voltmeter Ammeter Electric Power Meter Current Voltage Monitoring

U Shaped Hook with Screw Kitchen Wall Hanging Cabinet Cupboard Stainless Steel Door Home Storage Hook Practical Hat Organizer

KOLIKOLI Handheld showerhead Clean water filter element Boosting water conservation 5-speed water outlet mode Bathroom Shower Head Kit

KEN Diamond Core Drill 110mm 1400W 6110B for Drilling Holes

Full Copper Extended Wall-Mounted Faucet for Washing Machine Special Household Mop Pool Professional Kitchen Sink Tap

Retekess TD112 Pager System: A Waterproof Restaurant Call Solution

2Core Cable Insulated PVC Power Cord UL2468 10M 16-26AWG boston copper speaker wire Red /Black Wire