Universal Metal Repair Agent: A Comprehensive Guide

Universal Metal Repair Agent: A Comprehensive Guide

Metalworking professionals and DIY enthusiasts alike often face challenges when it comes to repairing metal components. Fortunately, Universal Metal Repair Agents, such as strong welding adhesives and high-temperature resistant metal repair agents, can help address these issues effectively. In this article, we will explore the world of Universal Metal Repair Agents, discussing their key features, benefits, types, and applications.

What is a Universal Metal Repair Agent?

A Universal Metal Repair Agent is a versatile adhesive designed to bond various metals, including steel, aluminum, brass, and copper. These agents offer a strong, durable bond that can withstand high temperatures and extreme conditions. They come in different forms, such as pastes, liquids, and powders, allowing users to choose the best option for their specific needs.

Key Features & Benefits

- Strong bond strength: Universal Metal Repair Agents provide a strong, durable bond that can withstand high temperatures and extreme conditions.

- Versatility: These agents can be used on various metals, including steel, aluminum, brass, and copper.

- Easy application: Universal Metal Repair Agents come in different forms, such as pastes, liquids, and powders, making them easy to apply.

- High temperature resistance: Some Universal Metal Repair Agents are designed to withstand temperatures up to 600°F (315°C).

Types of Universal Metal Repair Agents

Universal Metal Repair Agents come in various forms, including:

- Strong welding adhesives: These adhesives provide a strong bond between metal components, making them ideal for repairing damaged parts.

- Electric welding glue for castings: These adhesives are specifically designed for electric welding applications, providing a strong bond between metal castings.

- High-temperature welding adhesive: These adhesives are designed to withstand high temperatures, making them ideal for use in extreme conditions.

How to Use a Universal Metal Repair Agent

Using a Universal Metal Repair Agent is a straightforward process that involves preparing the surface, applying the adhesive, and allowing it to cure.

Preparing the Surface

Before applying a Universal Metal Repair Agent, it's essential to prepare the surface by cleaning it thoroughly. Remove any dirt, oil, or grease using a degreaser or solvent. Once the surface is clean, roughen it slightly using sandpaper or a wire brush to improve adhesion.

Applying the Adhesive

Apply the Universal Metal Repair Agent according to the manufacturer's instructions. Most adhesives come in tubes or containers, making them easy to apply. Spread the adhesive evenly over the surface, ensuring that it covers the entire area. Allow the adhesive to set for a few minutes before joining the metal components.

Curing Time & Temperature

The curing time and temperature required for a Universal Metal Repair Agent vary depending on the type of adhesive used. Most adhesives require a curing time of 24 hours at room temperature. However, some high-temperature adhesives may require higher temperatures to cure properly.

High-Temperature Welding Adhesive: A Closer Look

High-temperature welding adhesives are designed to withstand extreme temperatures, making them ideal for use in applications such as automotive, aerospace, and industrial manufacturing. These adhesives provide a strong bond between metal components, even in high-temperature environments.

High-Temperature Applications

High-temperature welding adhesives are commonly used in applications such as:

- Automotive exhaust systems

- Aerospace components

- Industrial machinery

Electric Welding Glue for Castings

Electric welding glue for castings is a specialized adhesive designed for electric welding applications. It provides a strong bond between metal castings, making it ideal for repairing damaged parts.

Strong Welding Adhesive: Key Considerations

When choosing a strong welding adhesive, consider the following factors:

Durability & Strength

Look for adhesives that offer strong bond strength and durability, even in extreme conditions. Adhesives with high tensile strength and elongation properties are ideal for applications that require a strong bond.

Compatibility with Various Metals

Choose adhesives that are compatible with various metals, including steel, aluminum, brass, and copper. This will ensure that the adhesive can be used on a wide range of metal components.

Conclusion

Universal Metal Repair Agents are versatile adhesives designed to bond various metals, providing a strong, durable bond that can withstand high temperatures and extreme conditions. By understanding the key features, benefits, types, and applications of Universal Metal Repair Agents, users can choose the best option for their specific needs and achieve reliable, long-lasting repairs.

aining.ph

Review

You May Also Like

【Local Shipping】Desoldering Pump Picker SS-02 Professional Soldering Tool Desoldering Pump Picker Removal Tool

Fire Safety Exit Sign Emergency Escape Guide Light AC Single Double Face 110-240V For Supermarket

Centrifugal Switch US 37mm ID WEG: A Comprehensive Guide

J.LD TOOL Magnetic Nut Socket /Tek Screw Bits(12pcs/SET)

Jozoo 250g Wall Repairing Ointment: A Universal Mending Paste

Bathroom Drain Cover Anti-Bug Smell Eliminator Silicone Pad Sewer Drain Cover Odor Proofing Tool Household Essential

Polocat 100Pcs/bag Disposable Cotton Swabs: A Comprehensive Guide

Smart Lighting Switch 10A: A Comprehensive Guide

304 Automatic Water Level Control Valve: A Comprehensive Guide

![[COD]20CM Universal Toilet Tank Flush Lever Chrome Toilet Wrench Iron Handle Toilet Wrench](https://img.lazcdn.com/g/ff/kf/Sa3ce297c5eb84281a12f9bee798d5be4G.jpg_300x300q80.jpg)

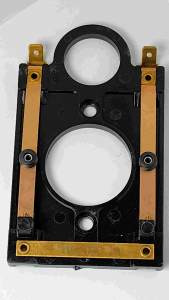

[COD]20CM Universal Toilet Tank Flush Lever Chrome Toilet Wrench Iron Handle Toilet Wrench

160/80/60pcs bullet butt connectors fully Insulated pvc quick splice electrical crimp terminal for automotive boat industrial