60W/120W CNC DC Buck Boost Converter Color Screen Adjustable Voltage Current Regulator Constant Power Step-Down Power Supply

60W/120W CNC DC Buck Boost Converter Color Screen Adjustable Voltage Current Regulator Constant Power Step-Down Power Supply

What is a CNC DC Buck Boost Converter?

A CNC DC Buck Boost Converter is a versatile power supply device designed to regulate voltage and current output. It is specifically engineered to cater to the needs of CNC machines, providing stable and consistent power output to ensure optimal performance. The converter is capable of stepping down voltage to match the required input of the CNC machine while maintaining constant power output.

Key Features & Benefits

The 60W/120W CNC DC Buck Boost Converter boasts a color screen interface, enabling users to easily adjust voltage and current settings. With its adjustable voltage and current regulator capabilities, the converter offers precise control over power output, ensuring the best possible performance for your CNC machine. Additionally, the converter's constant power step-down feature ensures stable power delivery, minimizing fluctuations and potential damage to your equipment.

Applications & Industries

The 60W/120W CNC DC Buck Boost Converter is widely used in various industries, including manufacturing, automotive, aerospace, and electronics. Its ability to provide stable power output makes it an ideal solution for CNC machines, laser cutters, plasma cutters, and other industrial equipment. By integrating this converter into your workflow, you can improve efficiency, reduce downtime, and enhance overall productivity.

How to Choose the Right CNC DC Buck Boost Converter

Selecting the appropriate CNC DC Buck Boost Converter is crucial for ensuring optimal performance and efficiency. Consider the following factors when making your decision:

- Power Output: Determine the required power output based on your CNC machine's specifications. The 60W/120W CNC DC Buck Boost Converter offers a wide range of power output options, making it suitable for various applications.

- Voltage and Current Requirements: Verify the voltage and current requirements of your CNC machine and select a converter that meets or exceeds these specifications.

- Color Screen Interface: Opt for a converter with a color screen interface for easy adjustment and monitoring of voltage and current settings.

- Adjustable Voltage and Current Regulator: Ensure the converter has adjustable voltage and current regulator capabilities to provide precise control over power output.

- Constant Power Step-Down Feature: Look for a converter with a constant power step-down feature to maintain stable power delivery and minimize fluctuations.

Common Mistakes to Avoid

When selecting a CNC DC Buck Boost Converter, avoid the following common mistakes:

- Underestimating Power Requirements: Failing to accurately assess power requirements may result in inadequate power output, leading to reduced performance and potential damage to your equipment.

- Neglecting Voltage and Current Specifications: Ignoring voltage and current specifications may cause compatibility issues and affect the overall performance of your CNC machine.

- Choosing a Converter Without a Color Screen Interface: Opting for a converter without a color screen interface may make it difficult to adjust and monitor voltage and current settings, compromising efficiency and accuracy.

- Overlooking Adjustable Voltage and Current Regulator Capabilities: Selecting a converter without adjustable voltage and current regulator capabilities may limit your ability to fine-tune power output, affecting performance and efficiency.

- Ignoring Constant Power Step-Down Feature: Neglecting a constant power step-down feature may result in unstable power delivery, causing fluctuations and potential damage to your equipment.

Installation & Setup Guide

Installing and setting up a CNC DC Buck Boost Converter is a straightforward process. Follow these steps to ensure a smooth installation and setup experience:

- Disconnect Power Supply: Before beginning the installation process, disconnect the power supply to your CNC machine to avoid potential electrical hazards.

- Mount the Converter: Securely mount the converter onto your CNC machine using the provided mounting hardware.

- Connect Input and Output Wires: Connect the input and output wires according to the manufacturer's instructions. Ensure proper connections to avoid short circuits or other electrical issues.

- Power On the Converter: Once the converter is properly connected, power it on and verify that it is functioning correctly.

- Adjust Voltage and Current Settings: Use the color screen interface to adjust voltage and current settings according to your CNC machine's specifications.

Troubleshooting Tips

If you encounter any issues during installation or operation, refer to the following troubleshooting tips:

- Check Connections: Verify that all input and output wires are securely connected to avoid short circuits or other electrical issues.

- Verify Voltage and Current Settings: Ensure that voltage and current settings match your CNC machine's specifications to avoid compatibility issues.

- Check for Faulty Components: Inspect the converter and associated components for any signs of damage or wear. Replace faulty components as necessary.

- Refer to Manufacturer's Documentation: Consult the manufacturer's documentation for additional troubleshooting tips and guidance.

Maximizing Performance & Efficiency

To maximize the performance and efficiency of your CNC DC Buck Boost Converter, follow these best practices and maintenance tips:

- Regular Cleaning: Clean the converter and associated components regularly to prevent dust buildup and ensure optimal performance.

- Monitor Voltage and Current Settings: Continuously monitor voltage and current settings to ensure they remain within safe operating limits.

- Perform Routine Maintenance: Conduct routine maintenance checks to identify potential issues and address them before they escalate.

- Keep Firmware Up-to-Date: Regularly update the converter's firmware to access the latest features and improvements.

Advanced Techniques & Customization Options

For users seeking to further enhance their CNC DC Buck Boost Converter's performance, consider the following advanced techniques and customization options:

- Custom Voltage and Current Profiles: Create custom voltage and current profiles tailored to specific applications or projects.

- Remote Monitoring and Control: Utilize remote monitoring and control capabilities to manage power output settings from a distance.

- Integration with Other Equipment: Integrate the converter with other equipment, such as CNC machines, laser cutters, or plasma cutters, to streamline workflows and improve efficiency.

GlobalLifestyle

Review

You May Also Like

LS32DM801UEXXP Samsung 32\" Smart Monitor M8 2023 / 3840x2160 / 16:9 / 4ms / 60Hz / Pivot / VA

Desktop Memory DDR3 4GB 8GB 1333MHz 1600MHz 1866MHz PC3 12800 240pin DIMM 1.5V RAM

Jungle Leopard Prism 4 RS Ultra Quiet Case Fan 12CM Cooling Desktop Silent ARGB Divine Light Synchronous Unlimited Mirror

ZEUSLAP 15.6inch 1920*1080P 60Hz IPS Panel Portable Monitor for Phone NS Laptop PC Second Screen Office Extend Monitor

Advanced USB C Power Stations with Quick Charges 3.0 Multiple Outlets Universal 110V Journey Essential for Abroad Use

2 Layers CPU Stand PC holder Computer Case Holder PC Storage Base Rack Desktop Tower Cart With Wheels CPU holder 202 Ratings

Type C to 3.5mm Sound Adapter Right Angle Type C to 3.5mm Headphone Plugs Dongle Aluminum Adapter for Smartphones Use

Portable 90 Degree Type C Male to 3.5mm Female Sound Adapter for Music and Call Management

3D Printer Accessories Brass Nozzle Cleaning Kit Cleaning Pin with Tweezers Wire Brush For MK8 3D Printer Accessories

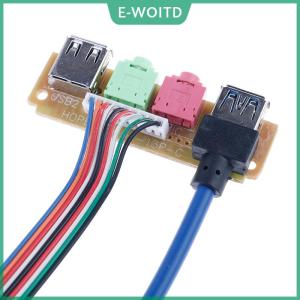

【E-WOITD】 USB 2.0+ 3.0 port chassis PC computer case audio front panel replace cable 70cm

MACHINIST X99 MR9S Motherboard LGA2011-3 kit Set Intel Xeon E5 2680 V4 CPU DDR4 2*8GB RAM ATX NVME SATA M.2 USB3.0 Four channels