Nitrile Black Sealing Rubber Ring O Model Repair Kit - Rubber O Ring Set - High Temperature Resistant Excavator Repair Kit

Nitrile Black Sealing Rubber Ring O Model Repair Kit - Rubber O Ring Set - High Temperature Resistant Excavator Repair Kit

Introduction to Nitrile Black Sealing Rubber Ring

What is a Nitrile Black Sealing Rubber Ring?

A nitrile black sealing rubber ring is a type of O-ring used for various sealing applications. These rubber rings are made from nitrile rubber, a synthetic rubber known for its excellent resistance to oil, fuel, and chemicals. The black color indicates that carbon black is added to the rubber compound, enhancing its physical properties, such as tensile strength and wear resistance.

Key Features of Nitrile Black Sealing Rubber Ring

- High temperature resistance: Nitrile black sealing rubber rings can withstand temperatures up to 120°C (248°F), making them suitable for use in various industrial applications.

- Wear resistance: These O-rings are designed to withstand friction and wear, providing long-lasting performance.

- Corrosion resistance: Nitrile black sealing rubber rings are resistant to corrosion caused by oils, fuels, and chemicals, making them ideal for use in harsh environments.

Product Specifications & Application

TZZF Brand Overview

TZZF is a leading manufacturer of high-quality nitrile black sealing rubber rings. Headquartered in Xingtai, Hebei, China, TZZF has been providing reliable sealing solutions for various industries since its establishment.

Standard Components & Specifications

The nitrile black sealing rubber ring O model repair kit is available in three standard sizes, A Blue National Standard, B Yellow Japanese Standard, and C Red American Standard. These O-rings are designed to meet the specific requirements of different industries and applications.

Applicable Range of Nitrile Black Sealing Rubber Ring

Nitrile black sealing rubber rings are widely used in various industries, including automobiles, machinery, decoration, electrical appliances, cylinders, bearings, pumps, water pipes, valves, doors and windows, coating, pulley rollers, chemical pipes, and others. These O-rings provide reliable sealing solutions for hole sealing, oil seal, water seal, dustproof seal, guide ring, fixed seal, shaft seal, rotary seal, and other sealing applications.

High Temperature Resistant Excavator Repair Kit

High Temperature Resistance & Wear Resistance

The high temperature resistant excavator repair kit includes nitrile black sealing rubber rings designed to withstand temperatures up to 120°C (248°F). These O-rings are also wear-resistant, ensuring long-lasting performance in harsh environments.

Corrosion Resistance & Other Properties

In addition to high temperature resistance and wear resistance, the nitrile black sealing rubber rings in the high temperature resistant excavator repair kit are also corrosion-resistant. They provide reliable sealing solutions for oil, fuel, and chemical applications.

Purpose of High Temperature Resistant Excavator Repair Kit

The high temperature resistant excavator repair kit is specifically designed for excavators and other heavy-duty machinery operating in harsh environments. It provides reliable sealing solutions for hole sealing, oil seal, water seal, dustproof seal, guide ring, fixed seal, shaft seal, rotary seal, and other sealing applications.

Installation & Maintenance Guide

How to Install the Nitrile Black Sealing Rubber Ring

- Clean the mating surfaces before installing the nitrile black sealing rubber ring.

- Apply a thin layer of lubricant to the O-ring and mating surfaces.

- Insert the O-ring into the groove, ensuring that it is centered and aligned properly.

- Assemble the components, applying even pressure to avoid damaging the O-ring.

Maintenance Tips for Nitrile Black Sealing Rubber Ring

- Regularly inspect the O-rings for signs of wear, damage, or contamination.

- Clean the O-rings and mating surfaces before reassembly.

- Replace worn or damaged O-rings promptly to prevent leaks and equipment failure.

Troubleshooting Common Issues

- If the O-ring is leaking, check for damage, contamination, or improper installation.

- If the O-ring is difficult to install, ensure that the mating surfaces are clean and lubricated.

- If the O-ring is damaged or worn, replace it with a new one.

Polyurethane seals factory

You May Also Like

Door Hook Home Bathroom Organizer 5 Hooks Coat Towel Hanger for Bathroom Kitchen Accessories Bracket

Kitchen Sink M10 304 Stainless Steel Braided Flexible Hose Cold And Hot Water Compatible Explosive Proof Water Supply Pipe

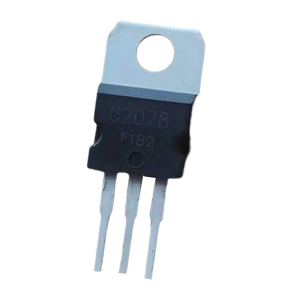

C2078 TO220 2SC2078 TO-220 2078 3A 80V Transistors Power Transistors

INGCO ANGLE GRINDER | AG900283P | TOOLS R TOYS | ING-POWERTOOLS

50mm HighBathroom Water Stopper Water Partition Dry And Wet Separation Flood Barrier Rubber Dam Silicon Water Blocker Dont Slip Silicone-Water-Barrier Shower Stopper Silicone Pipes - Lazada

【Free Shipping】 Portable Digital Pen Meter A3005 4000 Counts Digital DC AC Voltmeter for Electrical Diagnostics and Troubleshooting

30CM Dropside Lock With Plate / Hook Toggle Hasp Latch Delivery Frucks Buckle For Truck

Melo home 10A/30A Solar Charge Controller 12V/24V Battery Regulator Solar Panel Controller LCD Display

CPY Adjustable Wrench Set Tool Multifunctional Short Handle Large Opening Wrench Plumbing Tools Spanner

High-Quality 10 Inch Inflatable Wheels for Trolley & Wheelbarrow

1/3/5M Nano Tape Double Sided Tape Waterproof Transparent Non-Marking High End Adhesive Tape