Japanese Sharpening Stone: A Professional Guide

Japanese Sharpening Stone: A Professional Guide

What is a Japanese Sharpening Stone?

A Japanese sharpening stone, also known as a whetstone or water stone, is a tool used to sharpen knives, scissors, and other cutting tools. These stones are renowned for their ability to produce sharp, precise edges and are widely used by chefs, knife enthusiasts, and professionals worldwide.

Key Features of Japanese Sharpening Stones

Japanese sharpening stones have several distinguishing features that set them apart from other sharpening tools:

- High-Quality Materials: Made from natural or synthetic materials, such as Arkansas stone, aluminum oxide, or silicon carbide, Japanese sharpening stones offer exceptional durability and performance.

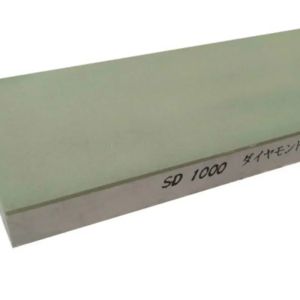

- Multi-Grit Options: Available in various grit levels, including 1000, 3000, 6000, and 12000 grit, these stones cater to different sharpening needs and knife types.

- Water-Based Lubrication: Japanese sharpening stones require water as a lubricant, which helps to prevent clogging and ensures a smooth sharpening process.

Types of Japanese Sharpening Stones

There are two primary types of Japanese sharpening stones:

- Natural Stones: These stones are made from natural materials, such as Arkansas stone or novaculite, and offer a more traditional sharpening experience.

- Synthetic Stones: These stones are made from synthetic materials, such as aluminum oxide or silicon carbide, and provide consistent performance and durability.

Choosing the Right Grit for Your Needs

Selecting the appropriate grit level is crucial for achieving optimal sharpening results. The following guidelines will help you match the right grit to your knife type and sharpening needs.

Understanding Grit Levels

Grit levels determine the coarseness or fineness of the sharpening stone. Here's a breakdown of the most common grit levels:

- 1000 Grit: Ideal for removing nicks, dents, and heavy wear from knives. This coarse grit level is best suited for initial sharpening or resharpening heavily damaged knives.

- 3000 Grit: Offers a medium-coarse grit level, perfect for refining the edge of a knife after using a coarser stone. This grit level is suitable for general sharpening and maintenance.

- 6000 Grit: Provides a fine grit level, ideal for honing and polishing the edge of a knife. This grit level is perfect for achieving a razor-sharp edge and removing minor imperfections.

- 12000 Grit: Offers an ultra-fine grit level, suitable for final honing and polishing. This grit level is perfect for achieving a mirror-like finish on the edge of a knife.

Matching Grit to Knife Type

Different knife types require different grit levels for optimal sharpening results. Here's a breakdown of the most common knife types and their recommended grit levels:

- Chef's Knives: Start with a 1000 grit stone to remove any nicks or dents, then move to a 3000 grit stone for refining the edge. Finish with a 6000 grit stone for honing and polishing.

- Serrated Knives: Use a 1000 grit stone to remove any burrs or nicks, then move to a 3000 grit stone for refining the edge. Serrated knives may require additional care and attention during the sharpening process.

- Paring Knives: Start with a 3000 grit stone for general sharpening and maintenance, then move to a 6000 grit stone for honing and polishing.

How to Use a Japanese Sharpening Stone

Using a Japanese sharpening stone requires proper technique and attention to detail. Follow these steps to ensure optimal sharpening results:

Preparing Your Stone & Knife

Before beginning the sharpening process, ensure your stone and knife are properly prepared:

- Soak the Stone: Place the stone in a shallow container of water for at least 10 minutes before use. This helps to lubricate the stone and prevent clogging.

- Clean the Knife: Remove any dirt, debris, or residue from the knife blade before sharpening.

The Sharpening Process

Follow these steps to sharpen your knife using a Japanese sharpening stone:

- Hold the Knife Properly: Hold the knife handle firmly with one hand and the blade with the other hand. Position the blade at a 20-degree angle to the stone.

- Apply Pressure: Apply gentle pressure to the blade while moving it back and forth across the stone. Use a consistent motion to maintain the angle and avoid damaging the blade.

- Repeat on Both Sides: Repeat the process on both sides of the blade, ensuring equal pressure and consistent motion.

- Move to Finer Grit: Once the desired edge is achieved, move to a finer grit stone for honing and polishing.

Maintaining Your Japanese Sharpening Stone

Proper maintenance of your Japanese sharpening stone ensures optimal performance and longevity:

- Clean the Stone: After use, rinse the stone with water and remove any debris or residue.

- Dry the Stone: Allow the stone to air dry completely before storing.

- Store the Stone: Store the stone in a cool, dry place to prevent moisture buildup and damage.

Professional Diamond Resin Grindstone: An Alternative Option

For those seeking an alternative to traditional Japanese sharpening stones, professional diamond resin grindstones offer several advantages:

Advantages of Diamond Resin Grindstones

- Durable and Long-lasting: Made from high-quality diamond particles embedded in a resin matrix, these grindstones offer exceptional durability and longevity.

- Consistent Performance: Diamond resin grindstones provide consistent performance, regardless of the sharpening stone's age or condition.

- Easy to Clean: These grindstones are easy to clean and maintain, requiring minimal effort and time.

How to Choose the Best Diamond Resin Grindstone

When selecting a diamond resin grindstone, consider the following factors:

- Grit Level: Choose a grit level that matches your sharpening needs and knife type.

- Size and Shape: Select a size and shape that fits your workspace and provides optimal control during the sharpening process.

- Price: Consider the price point and value for your budget.

Conclusion

Japanese sharpening stones offer exceptional performance and durability, making them a popular choice among knife enthusiasts and professionals worldwide. By understanding the different types, grit levels, and proper usage techniques, you can achieve optimal sharpening results and maintain the sharpness of your knives. If you're looking for an alternative option, professional diamond resin grindstones provide consistent performance and easy maintenance, making them a great choice for those seeking a reliable sharpening solution.

GlobalLifestyle

Review

You May Also Like

MasterZ - Zhang Xiao Quan High Quality Stainless Steel 6 Pieces Kitchen Knife with Wood Block/Kitchen Accessories D31090100S

450/750/1000/1500ML Glass Food Storage Canisters BPA-Free Kitchen Jars with Airtight Bamboo Lids for Pasta Coffee Beans&Candies

Multi-functional Drain Basket: A Must-Have for Your Kitchen Sink

28/30/32CM Non-Stick Pan Medical Stone Cooking Wok Granite Coating Frying Wok With Lid Suitable For All Stove

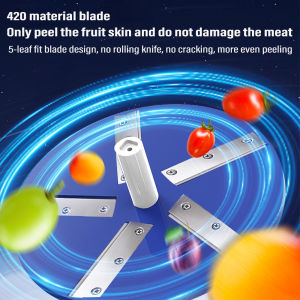

Automatic Fruit Peeler Intelligent Peeling Machine Portable Wireless Grape/tomato/Garlic Peeler for Home Fast Kitchen Supplies

6pc Vintage engraved glass cup Mini fruit wine cup Exquisite small glass One sip cup

Kitchen Timer Magnetic Mechanical Manual Digital Timer 60-Minutes Alarm Stainless Steel Cooking Timer

BINCOO Electric Kettle Constant Temperature Hand Brewed Coffee Pot Intelligent Temperature Controlled Thin Spout Pot for Home and Office Large Capacity 700ML

1PC Multi-Functional Silicone Spatula: A Must-Have Kitchen Tool

Automatic Stirring Coffee Mug Powered Glass Electric Mixing Cup 400ml Auto Mixer for Home and Office Use

From the Kitchen Transparent Rotatable Kitchen Condiment Storage Rack Seasoning 360° Turntable Transparent Box