12V 200W Fuel Delivery: A Comprehensive Guide

12V 200W Fuel Delivery: A Comprehensive Guide

Diesel pumps and oil transfer systems play a vital role in various industries, from agriculture to construction. In this guide, we will delve into the world of diesel pumps, electric tools with alligator clips, direct current kits for pumps, and portable electric fuel transfer pumps. We'll cover everything you need to know about these essential components and how they work together to deliver efficient fuel transfer solutions.

Understanding Diesel Pumps & Oil Transfer

What is a Diesel Pump?

A diesel pump is a mechanical device used to move diesel fuel from one location to another. It is commonly used in automotive applications, such as fuel delivery systems in diesel engines, and industrial settings, like oil refineries and storage facilities. Diesel pumps come in various types, including rotary vane, gear, and diaphragm pumps, each designed for specific applications and performance requirements.

How Does an Oil Transfer Pump Work?

An oil transfer pump works by creating a vacuum or suction force to draw liquid from one container and push it through a hose or pipe to another container. In the case of diesel pumps, they use a combination of mechanical components, such as gears, vanes, or diaphragms, to move the fuel through the system. This process ensures a consistent flow of diesel fuel, which is crucial for maintaining optimal engine performance.

Key Features of Diesel Pumps

Diesel pumps offer several key features that make them indispensable in various industries:

- High efficiency: Diesel pumps are designed to deliver maximum performance with minimal energy consumption.

- Durability: Built with robust materials, diesel pumps can withstand harsh operating conditions and last for years.

- Reliability: With proper maintenance, diesel pumps provide consistent fuel delivery, minimizing downtime and maximizing productivity.

- Versatility: Available in different types and configurations, diesel pumps can cater to a wide range of applications and fuel requirements.

Electric Tools with Alligator Clips

How to Use an Electric Tool with an Alligator Clip

Electric tools with alligator clips are commonly used in automotive repair and maintenance tasks. To use one of these tools, simply attach the alligator clip to a grounded surface, such as a metal chassis or frame, and connect the tool to the power source. This setup allows you to safely operate the tool without worrying about electrical shock.

Benefits of Using Alligator Clips

Alligator clips offer several advantages when working with electric tools:

- Safety: By providing a secure ground connection, alligator clips reduce the risk of electrical shock.

- Convenience: Easy-to-use alligator clips allow you to quickly connect and disconnect your tool from the power source.

- Versatility: Alligator clips can be used with various electric tools, making them a valuable addition to any workshop or toolbox.

Safety Precautions for Electric Tools

When using electric tools with alligator clips, it's essential to follow these safety precautions:

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Ensure the tool is properly grounded before use.

- Never operate electric tools near flammable liquids or gases.

- Follow the manufacturer's instructions and guidelines for safe operation.

Direct Current Kits for Pumps

How to Install a Direct Current Kit for Pumps

Direct current (DC) kits are designed to convert standard AC-powered pumps into DC-powered units. To install a DC kit, follow these steps:

- Disconnect the pump from the power source.

- Remove the existing AC motor and wiring.

- Install the DC motor and wiring according to the manufacturer's instructions.

- Reconnect the pump to the power source.

Advantages of Using Direct Current Kits

Using a direct current kit for pumps offers several benefits:

- Increased efficiency: DC motors typically consume less energy than their AC counterparts, resulting in lower operating costs.

- Improved performance: DC motors provide better control over speed and torque, leading to more precise fuel delivery.

- Enhanced reliability: DC motors are less susceptible to electrical interference, reducing the risk of malfunctions.

Common Issues & Troubleshooting

When using direct current kits for pumps, you may encounter some common issues:

- Motor overheating: Ensure proper ventilation and cooling for the DC motor to prevent overheating.

- Inconsistent flow: Check the pump's impeller and filter for clogs or damage.

- Motor noise: Inspect the motor's bearings and shaft for wear or misalignment.

Portable Electric Fuel Transfer Pumps

How to Choose the Right Portable Pump

When selecting a portable electric fuel transfer pump, consider the following factors:

- Capacity: Determine the required flow rate and pumping capacity based on your application.

- Voltage: Choose a pump compatible with your power source, such as 12V or 24V.

- Material compatibility: Ensure the pump is made from materials suitable for the type of fuel you'll be transferring.

- Portability: Opt for a lightweight and compact design for easy transport and storage.

Applications & Industries for Portable Pumps

Portable electric fuel transfer pumps are widely used in various industries, including:

- Agriculture: For transferring fuel to tractors and other farm equipment.

- Construction: To refuel heavy machinery and vehicles on job sites.

- Marine: For refueling boats and yachts at marinas.

- Emergency services: To supply fuel to emergency response vehicles and generators.

Maintenance Tips for Portable Pumps

To extend the lifespan and maintain optimal performance of your portable electric fuel transfer pump, follow these maintenance tips:

- Regularly clean and inspect the pump for signs of wear or damage.

- Check and replace filters as needed to prevent clogs and maintain flow efficiency.

- Store the pump in a clean, dry location away from extreme temperatures and humidity.

- Follow the manufacturer's recommendations for lubrication and maintenance intervals.

Faultless

Review

You May Also Like

RF433 Wireless self-powered switch household remote control Push button switch Wall Light Switch

(Fast Delivery)10 Inch Metal Stud Crimper Aluminum Alloy Punching Pliers Plaster Drywall Tools For Fastening Metal Double Handed Keel Pliers

Woodworking Hole Opener Cutter 35mm Adjustable For Cabinet Doors With Included Dust Cover Hole Saw Accessories

Washable Toilet Seat Cover Waterproof Paste Type EVA Toilet Lid Cover Portable Toilet Covers Bathroom Accessories

2Pcs Nail-Free Adjustable Curtain Rod Holder Clamp Hooks Rod Bracket Holders Adhesive Wall Curtain Fixed Clip Hanging Rack Hook

OKDA Standard Toilet lid Quiet Toilet Lid Universal Slow Level Standard Size

10pcs Anti-clogging Small Brush Shower Head Cleaning Brush Shower Nozzle Pore Cleaning Brush

2106/161/169 Brushless Electric Wrench Drive Controler Circuit Board Switch

Professional Efficient Dust Shroud Collection Shield Attachment for Grinders Woodworking and Metalwork Easy Installation

Vessel NMC-2P NMS-2PR Screwdriver Bit Magnetizer and Demagnetizer Ring Magnetic Screwdriver Bit Holder Ring Screwdriver Bit Drive Holder

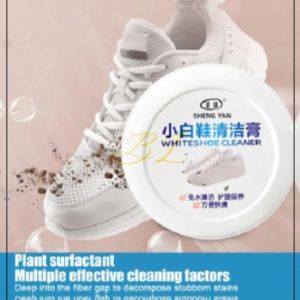

JOL-FASHION Multipurpose Cleaning Cream: The Ultimate Solution for White Shoes & Leather Bags