Numerical Control Lathes Thread Cutting Tool Bar SNR0008K11/0010K11/0012M11 with 11IR Thread Reamer End Milling Machine Tools

Numerical Control Lathes Thread Cutting Tool Bar SNR0008K11/0010K11/0012M11 with 11IR Thread Reamer End Milling Machine Tools

Introduction to Numerical Control Lathes & Thread Cutting Tool Bar

Numerical control lathes have revolutionized the manufacturing industry by providing precision, efficiency, and automation. These machines are capable of producing complex parts with minimal human intervention. A key component of numerical control lathes is the thread cutting tool bar, which enables the precise creation of threads on various materials.

Overview of Numerical Control Lathes

Numerical control lathes use computerized systems to control the movement of the machine's axes, allowing for accurate and repeatable operations. They are widely used in industries such as automotive, aerospace, and medical device manufacturing due to their ability to produce high-quality parts with tight tolerances.

Understanding Thread Cutting Tool Bars

Thread cutting tool bars are essential components of numerical control lathes, providing the necessary tools to create threads on various materials. These tool bars can accommodate multiple cutting tools, allowing for efficient and accurate thread production.

Exploring SNR0008K11 & 11IR Thread Reamer

The SNR0008K11 thread cutting tool bar is a versatile and reliable option for numerical control lathes. Its compact design and robust construction make it suitable for a wide range of applications.

SNR0008K11 Features & Benefits

- Compact design for easy installation and operation

- High-quality materials ensure durability and longevity

- Compatible with various numerical control lathes, offering flexibility in use

- Easy-to-use interface for seamless integration into existing manufacturing processes

How to Use 11IR Thread Reamer

The 11IR thread reamer is designed to work in conjunction with the SNR0008K11 thread cutting tool bar, providing accurate and efficient thread production. Here are some best practices for using the 11IR thread reamer:

- Ensure proper alignment of the reamer with the workpiece before beginning the threading process.

- Adjust the feed rate and spindle speed according to the material being worked on.

- Monitor the cutting process closely to ensure optimal performance and prevent damage to the tool or workpiece.

End Milling Machine Tools & Their Applications

End milling machine tools are essential components of numerical control lathes, providing the necessary tools to perform various operations such as face milling, contouring, and slotting.

Types of End Milling Machine Tools

There are several types of end milling machine tools available, including:

- Solid carbide end mills: Ideal for high-speed machining applications due to their excellent heat resistance and wear resistance.

- High-speed steel end mills: Suitable for general-purpose machining applications, offering good durability and cost-effectiveness.

- Indexable insert end mills: Provide versatility and cost savings by allowing the replacement of worn inserts rather than the entire tool.

Best Practices for Using End Milling Machine Tools

To ensure optimal performance and longevity of end milling machine tools, follow these best practices:

- Choose the appropriate tool for the material being worked on.

- Set the correct feed rate and spindle speed according to the tool's specifications.

- Monitor the cutting process closely to detect any signs of wear or damage.

Conclusion & Future Prospects

Numerical control lathes equipped with thread cutting tool bars like the SNR0008K11 and end milling machine tools offer manufacturers the ability to produce high-quality parts with precision and efficiency. By understanding the features and benefits of these tools, as well as best practices for their use, manufacturers can maximize their productivity and competitiveness in today's market.

Summary of Key Points

- Numerical control lathes provide precision, efficiency, and automation in manufacturing.

- Thread cutting tool bars like the SNR0008K11 enable accurate thread production.

- End milling machine tools offer versatility and cost-effectiveness for various machining operations.

- Best practices for using these tools include choosing the appropriate tool, setting correct parameters, and monitoring the cutting process closely.

Potential Advancements in Numerical Control Lathes & Thread Cutting Tool Bar

As technology continues to evolve, we can expect to see further advancements in numerical control lathes and thread cutting tool bars. These may include improved materials, enhanced tooling designs, and more sophisticated computerized systems for even greater precision and efficiency. }

TAO Garden

Review

You May Also Like

Aerodynamic Circular Connector P20 Plug & Socket: A Comprehensive Guide

MaxPlus Wire Stripper Knife Crimper Plier Small Crimping Cable Stripping Multifunctional Tool

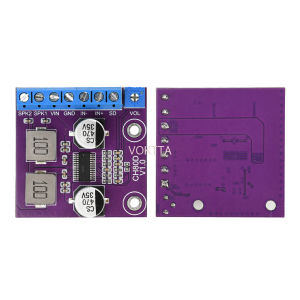

CH80D 80W audio amplifier module stereo serial port D-class single channel voice DC 5-26V

DOORMAX WHOLESALE Heavy Duty Barrel Bolt 100 PCS

Sturdy Stainless Steel Sink Strainer Basket with High Density Materials for Preventing Clogs in Kitchen Sinks Use

Techlife & Rixme Five-Speed Pressurized Shower Head Set: A Comprehensive Guide

DIY Silicone Molding Putty Kit - Flexible Rubber for Resin Casting, 3D Printing & Crafts Easy Mix Ratio (1A:1B) Beginner Friendly

TSUNODA King TTC Spring Loaded Wire Cutter Cable Cutting Plier Cut Copper Core Cable IV Cable CA-22/CA-22S/CA-38/CA-60/OCA-60

Automatic Tape Dispenser with Tape Packaging Tape Cutter White Tape Cutting Tool Office Supplies for Gift Packaging

2.2V Flashlight Bulb For Student Projects E10 E-10 (Per Piece)

500g White Paint Renovation Wall Roller Paint Brush To Cover Graffiti Stains Cleaning Roller Brush