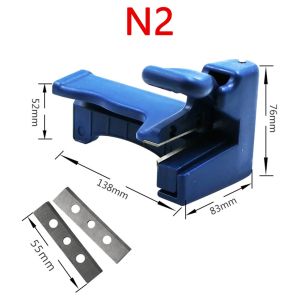

Trimmer Banding Machine Wood Edge Trimming Tool Woodworking Hardware Tools

Trimmer Banding Machine Wood Edge Trimming Tool Woodworking Hardware Tools

Precision wood cutting and edge trimming play a significant role in the woodworking industry. From small-scale projects to large-scale production, achieving clean, precise cuts and edges is essential for producing high-quality finished products. This article will explore the Trimmer Banding Machine, a powerful tool designed specifically for precision wood cutting and edge trimming. We'll discuss its key features, benefits, and how to choose the right wood edge trimming tool for your needs.

What is a Trimmer Banding Machine?

A Trimmer Banding Machine is a specialized woodworking machine designed to cut and trim the edges of wood panels, sheets, and boards with exceptional precision. These machines are commonly used in woodworking shops, furniture manufacturing facilities, and other industries that require accurate edge trimming.

Key Features of Trimmer Banding Machines

Trimmer Banding Machines offer a range of features that make them ideal for precision wood cutting and edge trimming:

- High Precision: Trimmer Banding Machines provide high accuracy, allowing for clean, straight cuts and edges with minimal waste.

- Versatility: These machines can handle various types of wood, including hardwoods, softwoods, plywood, and MDF.

- Adjustability: Trimmer Banding Machines often feature adjustable settings, allowing users to customize the cut depth and angle to suit specific project requirements.

- Safety Features: Many Trimmer Banding Machines come equipped with safety features, such as blade guards and emergency stop buttons, to protect users from potential accidents.

Benefits of Using Trimmer Banding Machines

Using a Trimmer Banding Machine offers several advantages for woodworking projects:

- Improved Efficiency: Trimmer Banding Machines can significantly increase productivity by streamlining the edge trimming process and reducing manual labor.

- Enhanced Quality: With their high precision and adjustability, Trimmer Banding Machines produce consistent, high-quality cuts and edges that enhance the overall appearance of finished products.

- Cost Savings: By minimizing waste and maximizing material usage, Trimmer Banding Machines can help reduce material costs and improve profitability.

Choosing the Right Wood Edge Trimming Tool

Selecting the appropriate wood edge trimming tool is crucial for achieving optimal results in your woodworking projects. Consider the following factors when choosing a wood edge trimming tool:

- Project Requirements: Determine the specific needs of your project, including the type of wood, cut depth, and angle requirements.

- Budget: Establish a budget for your wood edge trimming tool, taking into account the cost of the machine, maintenance, and replacement parts.

- User Skill Level: Consider your skill level and experience with woodworking tools when selecting a wood edge trimming tool.

Comparing Different Types of Wood Edge Trimming Tools

There are several types of wood edge trimming tools available, each with its own set of advantages and disadvantages. Some popular options include:

- Manual Trimmers: These handheld tools require manual operation and are ideal for small-scale projects or DIY enthusiasts.

- Electric Trimmers: Electric trimmers offer more power and speed than manual trimmers, making them suitable for larger projects.

- Trimmer Banding Machines: As discussed earlier, Trimmer Banding Machines provide exceptional precision and efficiency for edge trimming tasks.

How to Use a Trimmer Banding Machine for Precision Wood Cutting

Operating a Trimmer Banding Machine requires proper technique and attention to detail. Follow these steps to ensure accurate cuts and edges:

- Prepare the Machine: Set up the Trimmer Banding Machine according to the manufacturer's instructions, ensuring that all components are properly aligned and adjusted.

- Adjust Settings: Adjust the cut depth and angle settings to match your project requirements.

- Load the Wood: Place the wood panel, sheet, or board onto the machine, securing it in place with clamps or other holding devices.

- Start the Machine: Turn on the Trimmer Banding Machine and begin trimming the edge of the wood, following the desired path.

- Monitor Progress: Continuously monitor the cutting process, making adjustments as needed to maintain accuracy and consistency.

Best Practices for Maintaining Edge Trimming Equipment

To ensure optimal performance and longevity of your Trimmer Banding Machine and other edge trimming tools, follow these best practices:

- Regular Maintenance: Clean and inspect your equipment regularly, replacing worn or damaged components as necessary.

- Sharpen Blades: Keep blades sharp to maintain cutting efficiency and prevent damage to the wood.

- Store Properly: Store your equipment in a clean, dry location to protect it from dust, moisture, and other environmental factors.

Woodworking Hardware Tools: Enhancing Your Crafting Experience

In addition to Trimmer Banding Machines and wood edge trimming tools, there are several other woodworking hardware tools that can enhance your crafting experience. These include:

- Clamps: Clamps help secure wood pieces in place during cutting, gluing, and assembly processes.

- Drills: Drills are essential for creating holes and mounting hardware in wood projects.

- Sandpaper: Sandpaper is used to smooth rough surfaces and prepare wood for finishing.

The Importance of Quality Woodworking Hardware Tools

Investing in quality woodworking hardware tools is crucial for achieving professional results in your projects. High-quality tools provide better precision, durability, and safety, ultimately leading to improved productivity and satisfaction.

Additional Tools to Complement Your Trimmer Banding Machine

To maximize the capabilities of your Trimmer Banding Machine, consider incorporating these complementary tools into your woodworking setup:

- Jointer: A jointer helps flatten and straighten the edges of wood boards, preparing them for accurate cuts and joints.

- Planer: A planer is used to reduce the thickness of wood boards, ensuring uniformity and consistency in your projects.

- Router: A router allows you to create intricate designs, patterns, and profiles on the edges of wood pieces.

Conclusion: Maximizing Efficiency with Precision Wood Cutting & Edge Trimming Equipment

Precision wood cutting and edge trimming are essential skills for any woodworker. By investing in high-quality Trimmer Banding Machines and complementary woodworking hardware tools, you can significantly improve the efficiency, accuracy, and overall quality of your projects. Remember to choose the right tools for your needs, follow best practices for maintenance and operation, and continuously hone your skills to become a master woodworker.

WSneIbuG

Review

You May Also Like

【🔥hot】3M Transparent Double-sided Adhesive Non Marking Nano Tape Strong Adhesive Waterproof Multifunctional Fixed Stickers for Carpets Toothbrush HoldersSpring Festival Couplets(in stock)

Bathroom Hair Drain Cleaner: A Comprehensive Guide

798 High Quality Series Accessories White Handle/Black Handle

2/4/6PCS Transparent Fixing Patch Strong Plastic Hooks Hanging Shelf Hooks Wall Storage Rack

DIYMO Automotive glass glue black polyurethane sealant sheet metal glue windshield special car waterproof soft bag strong glue

Hair Rings Hair Clips Adhesive Hooks Toilet Storage Rack Headband Holder Plastic Jewelry Storage Rack

Portable Welding Machine MlG/TIG/MMA 3IN1 Gasless Inverter Welding Machine lGBT DC Inverter We

gu49 MALL 1Pc M12 sensor connector 3 4 5 pin male female straight right angle plug

Stainless Steel 304/316 Card Sleeve Straight through Board Insertion Fitting Board Heterodyne Fitting 6 8 10 12 14 1/8 1/4

20PCS Self Drilling Anchor Screw Drywall Gypsum Board Self Tapping Fast Easy Installation

GI Turn Buckle Heavy Duty Wire Rope Tensioner Turnbuckle Hook & Eye 6-24mm Tensioner Screw Bolt