Miniature NSK Ball Bearings Small Size Deep Groove Ball Bearings P5 Precision Single Row Japan Made Bearing Steel Material

Miniature NSK Ball Bearings Small Size Deep Groove Ball Bearings P5 Precision Single Row Japan Made Bearing Steel Material

What Are Miniature NSK Ball Bearings?

Miniature NSK ball bearings are small-sized ball bearings manufactured by NSK, a renowned Japanese company known for its precision and quality. These miniature ball bearings are designed to meet the demands of various industries, including automotive, aerospace, medical, and electronics.

How They Work

Miniature NSK ball bearings operate using a set of balls that rotate between two races, one fixed and the other rotating. This design minimizes friction, allowing the bearing to support loads and provide smooth rotational motion.

Benefits of Using Miniature NSK Ball Bearings

Using miniature NSK ball bearings offers numerous benefits, including:

- Compact Design: These bearings are small, making them ideal for applications where space is limited.

- High Precision: NSK's manufacturing process ensures high precision and accuracy, leading to reliable performance.

- Durability: Made from high-quality materials, these bearings are designed to withstand harsh environments and last longer.

Small Size Deep Groove Ball Bearings

Small size deep groove ball bearings are another type of miniature bearing that features a deep groove design. This design provides enhanced load-carrying capacity and improved performance in various applications.

Applications of Small Size Deep Groove Ball Bearings

Small size deep groove ball bearings are commonly used in industries such as:

- Automotive: For components like steering systems and suspension systems.

- Aerospace: For various aircraft components, including landing gear and control surfaces.

- Medical: In medical devices and equipment, such as surgical instruments and diagnostic machines.

Advantages of Small Size Deep Groove Ball Bearings

Some advantages of using small size deep groove ball bearings include:

- Enhanced Load-Carrying Capacity: The deep groove design allows these bearings to support heavier loads.

- Improved Performance: With better load distribution, these bearings provide smoother rotational motion and reduced wear.

- Compact Design: Like miniature NSK ball bearings, these bearings are small and can be used in tight spaces.

P5 Grade Ball Bearings

P5 grade ball bearings are high-precision bearings that meet specific standards set by the International Organization for Standardization (ISO). These bearings are designed to provide exceptional accuracy and performance.

Understanding P5 Grade Ball Bearings

P5 grade ball bearings have a tolerance class of P5, which means they meet the highest level of precision and accuracy according to ISO standards. This makes them ideal for applications requiring precise motion control and minimal vibration.

How to Choose the Right P5 Grade Ball Bearing

When selecting a P5 grade ball bearing, consider the following factors:

- Load Capacity: Ensure the bearing can support the required load.

- Speed: Check if the bearing can operate at the desired speed without excessive heat generation.

- Precision: Verify that the bearing meets the required level of accuracy and performance.

Precision Single Row Bearings

Precision single row bearings are another type of high-precision bearing that features a single row of balls. These bearings are designed to provide accurate and smooth rotational motion.

Applications of Precision Single Row Bearings

Precision single row bearings are commonly used in industries such as:

- Automotive: For components like wheel hubs and transmission systems.

- Aerospace: In aircraft engines and landing gear systems.

- Medical: In medical devices and equipment, such as imaging machines and surgical robots.

Benefits of Using Precision Single Row Bearings

Some benefits of using precision single row bearings include:

- Accurate Motion Control: These bearings provide precise and smooth rotational motion, making them ideal for applications requiring minimal vibration.

- Longer Life: Due to their high precision and quality materials, these bearings can last longer than standard bearings.

- Wide Range of Applications: Precision single row bearings can be used in various industries and applications, making them versatile and valuable.

Japan Made Bearing Steel Material

Japan made bearing steel material is known for its high quality and durability. This material is used to manufacture high-precision bearings, such as miniature NSK ball bearings, small size deep groove ball bearings, P5 grade ball bearings, and precision single row bearings.

Importance of Japan Made Steel Material

Japan made bearing steel material is crucial for producing high-quality bearings because it:

- Ensures High Precision: The material's properties allow for the production of bearings with exceptional accuracy and performance.

- Provides Durability: Bearings made from Japan made steel material can withstand harsh environments and last longer.

- Supports Various Applications: This material can be used to manufacture bearings for various industries and applications, making it versatile and valuable.

How to Choose the Right Japan Made Steel Material

When selecting Japan made bearing steel material, consider the following factors:

- Quality: Ensure the material meets high standards of quality and precision.

- Durability: Verify that the material can withstand the required load and operating conditions.

- Compatibility: Check if the material is compatible with the desired application and industry.

TAO Auto Fit

You May Also Like

Car Seat Gap Organizer: A Multifunction Console Crevice Storage Box

Car Windshield Snow Shield Freezing Protection Cover Magnetic Absorption Thickened Winter Anti-ice Frost Cover Simple Style Aluminum Foil

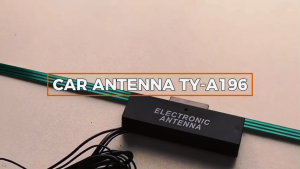

MCPA Car Roof Mast Stereo Radio FM AM Amplified Antenna for Cars Universal (10763)

2Pcs Motorcycle Indicator Light Lamp Holder Metal Fork Ear Clamps Rear Turn Signal Relocation Bracket

Disc Brake Bracket 260mm For AEROX V1 V2 Front Big Disc Bracket

Dual Color Mini LED Light para sa Motorcycle & Off-Road – High/Low Beam 16W

Anak KD-40 Helmet: A Comprehensive Guide for Ages 4 to 12

Balanced Extension Bar Support for Nine Number MMAX2/M3/N3/F90M/N Mini Bull UMAX/NXT/FXT Electric Vehicle Accessories

LED Stop Lamp Bulb 24V Freight Car Taillight Bulb Turn Signal Driving Reversing Lamp Single Tail Boxer Flash Stop Lamp

Car Bumper Guard Anti Collision Strip Rubber Crescent Shape Tape Scratch Impact Resistant Paint Protection for Auto Vehicle

MaxPlus Multifunctional Cleaning Brush Car Interior Cleaning Tool Keyboard Brushes