100/20g Solder Wire: A Comprehensive Guide

100/20g Solder Wire: A Comprehensive Guide

Introduction to 100/20g Solder Wire

Soldering is a crucial process in electronics assembly, allowing components to be joined securely and efficiently. The 100/20g solder wire is a popular choice among professionals and hobbyists alike, thanks to its versatility and ease of use. This comprehensive guide will explore the key features, applications, and various types of solder wire, including easy melt soldering core, clean rosin flux, low temperature solder wire, and tin roll soldering wire.

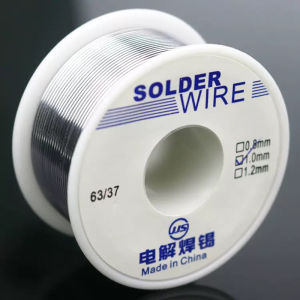

Key Features of 100/20g Solder Wire

The 100/20g solder wire offers several advantages, making it an ideal choice for a wide range of applications. It has a diameter of 0.8mm (20 gauge) and a length of 100 meters, providing ample material for even the most demanding projects. The wire consists of a 60/40 tin-lead alloy, which offers excellent wetting properties and strong mechanical strength. It also features a rosin flux core, which helps to clean and prepare the surfaces being joined, ensuring a strong bond.

Applications of 100/20g Solder Wire

The 100/20g solder wire is suitable for various applications, including electronics assembly, prototyping, and repair work. Its versatility makes it a valuable tool for professionals working in industries such as telecommunications, automotive, aerospace, and consumer electronics. Hobbyists and DIY enthusiasts also appreciate the wire's ease of use and affordability.

Understanding Easy Melt Soldering Core

Easy melt soldering core is a type of solder wire that melts at a lower temperature than traditional solder wires. This makes it ideal for applications where heat-sensitive components are involved, such as surface mount technology (SMT) assemblies.

Advantages of Easy Melt Soldering Core

The advantages of easy melt soldering core include:

- Lower melting point, reducing the risk of damaging heat-sensitive components

- Faster wetting, resulting in improved solder joint quality

- Reduced energy consumption during soldering

Disadvantages of Easy Melt Soldering Core

While easy melt soldering core offers several benefits, it also has some drawbacks, including:

- Lower tensile strength compared to traditional solder wires

- Potential for cold solder joints if not applied correctly

Exploring Clean Rosin Flux

Clean rosin flux is a type of flux used in soldering that helps to remove oxidation from the surfaces being joined. It is designed to leave minimal residue after soldering, making it ideal for applications where cleanliness is essential.

How Clean Rosin Flux Works

Clean rosin flux works by chemically reacting with the oxidation on the surfaces being joined, breaking down the oxide layer and allowing the solder to flow freely. It also helps to improve wetting and reduce the formation of cold solder joints.

Benefits of Clean Rosin Flux

The benefits of using clean rosin flux include:

- Improved wetting and reduced cold solder joints

- Minimal residue left behind after soldering

- Reduced risk of corrosion and electrical shorts

Low Temperature Solder Wire: An Overview

Low temperature solder wire is designed to melt at lower temperatures than traditional solder wires, making it ideal for applications where heat-sensitive components are involved.

Advantages of Low Temperature Solder Wire

The advantages of low temperature solder wire include:

- Lower melting point, reducing the risk of damaging heat-sensitive components

- Faster wetting, resulting in improved solder joint quality

- Reduced energy consumption during soldering

Disadvantages of Low Temperature Solder Wire

While low temperature solder wire offers several benefits, it also has some drawbacks, including:

- Lower tensile strength compared to traditional solder wires

- Potential for cold solder joints if not applied correctly

Tin Roll Soldering Wire: A Closer Look

Tin roll soldering wire is a type of solder wire that consists of a tin alloy, which offers excellent wetting properties and strong mechanical strength.

Advantages of Tin Roll Soldering Wire

The advantages of tin roll soldering wire include:

- Excellent wetting properties, resulting in strong solder joints

- Strong mechanical strength, providing reliable connections

- Low cost compared to other types of solder wires

Disadvantages of Tin Roll Soldering Wire

While tin roll soldering wire offers several benefits, it also has some drawbacks, including:

- Potential for corrosion if not used correctly

- Lower melting point compared to lead-based solder wires

GlobalLifestyle

You May Also Like

5pcs Damaged Screw Remover Set Stripped Broken Screw Bolt Remover and Extractor Drill Bit Set With Storage Box

20254Pcs Detachable Zinc Square Drop Down Cabinet Hinge Black Silver

Kitchen Faucet Fixed Nut Goose Neck Cold Faucet Accessory Pack 2 Parts Water Purifier Faucet Cap Kitchen Sink Water Valve Parts

100% Original Toka Grinding Disc for Metal Grinder Disc 4 7 Wheel Abrasive Disc

Wadfow 2pcs Reciprocating Saw Blades for Wood WJT611D WAD-HT OSOS

6 "/8"/10 "/12"/15 "inch adjustable wrench universal adjustable wrench automotive maintenance and repair tool sliding wrench

VEML7700 Ambient Light Sensor Module: 120k Lux Light Measuring 3.3V 5V I2C IIC for Arduino and Raspberry Pi

2PCS Wrench Tools Set Snap and Grip Universal Wrenches Tools Set Original Hardware Sale Wrench for Motorcycle Multi-function Wrench Spanner 9-32mm

Japanese Sewer Collector Filter Anti Clogging Bathroom Swirl Floor Drain

Copper Basin Foot Pedal Valve Faucet For Home1

ECOCO by renemos: A Comprehensive Guide to Silicone Floor Drain Covers & Water Stoppers