Wu Hydraulic Oil Filter Strainer: Customizable Solutions for Injection Molding Machines

Wu Hydraulic Oil Filter Strainer: Customizable Solutions for Injection Molding Machines

Understanding the Importance of Hydraulic Oil Filter Strainers

Hydraulic oil filter strainers play a crucial role in maintaining the optimal performance and longevity of hydraulic systems, particularly injection molding machines. These devices remove contaminants from the hydraulic fluid, ensuring clean and efficient operation.

How Hydraulic Oil Filter Strainers Protect Your Equipment

Contaminants such as dirt, dust, and metallic particles can severely damage hydraulic components, leading to increased wear and tear, reduced efficiency, and potential equipment failure. By removing these contaminants, hydraulic oil filter strainers help protect your equipment, extend its lifespan, and minimize downtime.

Common Applications for Hydraulic Oil Filter Strainers

Hydraulic oil filter strainers are widely used in various industries, including manufacturing, automotive, aerospace, and construction. In the context of injection molding machines, strainers are essential for maintaining the cleanliness of hydraulic oil, which directly impacts the performance and efficiency of the machine.

Key Features of Wu Hydraulic Oil Filter Strainers

Wu Hydraulic Oil Filter Strainers offer a range of features tailored to meet the specific needs of injection molding machines. These include stainless steel industrial strainers, customizable strainer designs, and efficient performance.

Stainless Steel Industrial Strainers & Their Benefits

Wu Hydraulic Oil Filter Strainers utilize stainless steel industrial strainers, known for their durability, corrosion resistance, and ability to withstand harsh operating conditions. These strainers effectively remove contaminants from hydraulic oil, ensuring clean and efficient operation.

Injection Molding Machine Strainers: Performance & Efficiency

Wu Hydraulic Oil Filter Strainers are specifically designed for injection molding machines, offering superior performance and efficiency. These strainers effectively remove contaminants, reducing wear and tear on hydraulic components and minimizing downtime.

Customizable Strainer Designs: Tailoring to Your Needs

Wu Hydraulic Oil Filter Strainers offer customizable strainer designs, allowing users to tailor the strainer to their specific requirements. This flexibility ensures optimal performance and efficiency, regardless of the application.

Choosing the Right Strainer for Your Application

Selecting the appropriate hydraulic oil filter strainer is critical for maintaining optimal performance and efficiency in injection molding machines. Consider the following factors when choosing a strainer:

Factors to Consider When Selecting a Hydraulic Oil Filter Strainer

- Contaminant removal requirements

- Operating conditions

- Machine specifications

- Budget

Comparing Different Types of Strainers: Steel Wire vs. Stainless Steel

When choosing a hydraulic oil filter strainer, consider the differences between steel wire and stainless steel strainers. Steel wire strainers are cost-effective and suitable for less demanding applications, while stainless steel strainers offer superior durability and corrosion resistance.

Best Practices for Maintaining & Replacing Hydraulic Oil Filter Strainers

To ensure optimal performance and efficiency, follow these best practices for maintaining and replacing hydraulic oil filter strainers:

- Regularly inspect strainers for signs of wear or damage

- Clean strainers according to manufacturer guidelines

- Replace strainers at recommended intervals

- Monitor hydraulic oil quality and adjust maintenance schedule accordingly

TAO Home Tools

Review

You May Also Like

Kitchen Utensils Storage Box Dust-Proof Tableware Holder Utensils And Chopstick Plastic Storage Box Spoons And Forks Organizer With Cover (Grey/Brown)

5pcs Stainless Steel Japanese Style Food Storage Box / Household Refrigerator Freezer Container with Lid / Microwave-safe Food sealed Case

Portable Children's Water Cup: High-Temperature Resistant PPSU Material Drinking Bottle

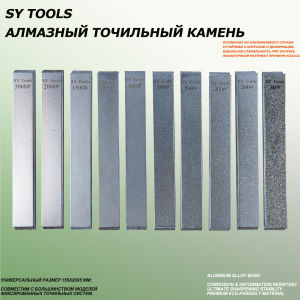

SyTools Diamond Sharpening Stone 80#-3000# Grit Aluminum Base for Angle Sharpeners 155x20x5mm Knife Sharpener Tool

8 Holes Long Strip Finger Silicone Finger Shape Tray Freeze Mould Pudding Jelly Biscuit Chocolate Mold Cookies Maker Fondant Cake Tools Hot Sale

Thickened Heat Resistant Glass Tea Cup Small Quantity Drinking Cup Japanese Style Home Use Wine Cup for Brewing Tea And Enjoying Snacks

Handheld Electric Milk Frother with Stainless Steel Stand for Coffee Espresso Latte

Manual Garlic Press Stainless Steel Garlic Mincer Chopping Garlic Tools Vegetable Cooking Crusher Kitchen Gadgets

Stainless Steel Flour Sifter Multi-purpose Powder Sugar Filter Baking Tools Powder Spreader Flour Sifter Sieve Kitchen Gadgets

Innovative Stainless Steel Kitchen Clamp Dish Plate Holder Anti-Scalding Multi-Functional Cooking Utensil by Eighteen Men Work

Multifunction Stainless Steel Fruit Vegetable Double Planing Grater Kitchen Gadget Peeler