Wear-Resistant Rubber Cable & Optical Cable Traction: A Comprehensive Guide

Wear-Resistant Rubber Cable & Optical Cable Traction: A Comprehensive Guide

Introduction to Wear-Resistant Rubber Cable & Optical Cable Traction

What is a Wear-Resistant Rubber Cable?

A wear-resistant rubber cable is a specially designed cable that has been reinforced with a rubber material that can withstand wear and tear over time. These cables are used in various applications, such as industrial machinery, power transmission, and telecommunications.

Understanding Optical Cable Traction

Optical cable traction refers to the process of pulling or installing optical cables through conduits or ducts. This process requires the use of specialized equipment, such as optical cable traction belts, to ensure the cables are installed safely and efficiently.

Why Choose a Wear-Resistant Rubber Cable?

Wear-resistant rubber cables offer several advantages over traditional cables, including increased durability, resistance to environmental factors, and improved performance in harsh conditions. These cables are ideal for applications that require long-term reliability and performance.

Key Components: Multi-Groove Belt & Slotted Extruder Belt

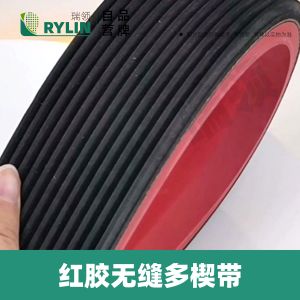

Multi-Groove Belt: Design & Functionality

A multi-groove belt is a specialized belt designed for optical cable traction applications. This belt features multiple grooves that allow for better grip and control during the installation process. The multi-groove belt is typically made of wear-resistant rubber material, which provides excellent durability and performance.

Slotted Extruder Belt: Benefits & Applications

The slotted extruder belt is another type of belt used in optical cable traction applications. This belt features slots that allow for easy installation and removal of cables. The slotted extruder belt is also made of wear-resistant rubber material, which provides excellent durability and performance.

Choosing the Right Belt for Your Needs

When choosing a belt for optical cable traction applications, it is important to consider factors such as the size and type of cable being installed, the distance of the installation, and the environmental conditions. Both the multi-groove belt and slotted extruder belt offer unique benefits and applications, so it is important to choose the right belt for your specific needs.

Flat Belt Pipe Traction: Installation & Maintenance

Installation Process: Step-by-Step Guide

Installing a flat belt pipe traction system requires careful planning and execution. Here is a step-by-step guide to installing a flat belt pipe traction system:

- Determine the size and type of cable being installed.

- Choose the appropriate belt for the installation.

- Install the belt onto the traction system.

- Attach the cable to the belt.

- Pull the cable through the conduit or duct using the traction system.

Maintaining Optimal Performance

To maintain optimal performance of a flat belt pipe traction system, regular maintenance is required. This includes cleaning the belt and traction system, checking for wear and tear, and replacing any damaged components.

Troubleshooting Common Issues

Common issues that may arise during flat belt pipe traction installation include cable damage, belt slippage, and traction system malfunction. To troubleshoot these issues, it is important to identify the root cause and take appropriate corrective actions.

Enhancing Efficiency: Multi-Wedge Belt & Wear-Resistant Solutions

Multi-Wedge Belt: Advantages & Considerations

The multi-wedge belt is another specialized belt used in optical cable traction applications. This belt features multiple wedges that allow for better grip and control during the installation process. The multi-wedge belt offers several advantages over other types of belts, including improved performance and efficiency.

Wear-Resistant Solutions for Long-Term Performance

To ensure long-term performance of optical cable traction systems, it is important to use wear-resistant solutions. This includes using wear-resistant rubber cables, belts, and other components that can withstand wear and tear over time.

Maximizing Efficiency in Optical Cable Traction

Maximizing efficiency in optical cable traction requires careful planning and execution. This includes choosing the right belt and other components, following proper installation procedures, and maintaining optimal performance through regular maintenance.

In conclusion, wear-resistant rubber cables and optical cable traction systems offer several advantages over traditional cables and systems. By understanding the key components and following best practices for installation and maintenance, you can ensure long-term reliability and performance in your optical cable traction applications.

TAO Hardware

Review

You May Also Like

Need. Widening Insect Proof Door and Window Seal Self-adhesive Sealing Strip Tape

LOTUS DEADBOLT SINGLE 8100/ET-US32D

Refrigerator Ice Blockage Tool Set Multifunctional Cleaning Drain Hole Deicing Home Use Pipe Unblocker Five-Piece Set

ItemMart 5m Nylon Tape Cable Organizer Tearable Cable Ties Strap Reusable Back to Back Nylon Straps Magic Rope

Home Storage Security Pas Key Safe Combination Operated Lock Storage Cabinet Key Safe

CHENJ Screwdrivers Tool Holder Organizer Hammer Pliers Wall Mounted Metal Storage Rack Organizer Workshop Workbench Small Tool Storage

300cm Floor Cable Wire Cover Cable Grip Organizer Self Adhesive Strip Floor Wire Carpet Cover

220V/60Hz 3inch Stainless Steel Deep Well Pump Single-Phase High Lift Submersible Bore Pump for Home/Farm/Irrigation

3M Strong Permanent Double Sided Tape Super Sticky Foam Tape Roll for Vehicle Car Wall Waterproof

12V/220V Mini Smart Thermostat Automatic Incubator Control System Temperature Humidity Control for Farm Chickens Ducks Geese

Multipurpose Tool Storage Roll Up Bag With 18 Compartments Water Resistant Fabric For Travel Profession Organized Work