Professional Drill Bit Sharpener: Multipurpose Drill Bits Grinding & High-Speed Steel Masonry Carbide Cobalt

Professional Drill Bit Sharpener: Multipurpose Drill Bits Grinding & High-Speed Steel Masonry Carbide Cobalt

Introduction to Professional Drill Bit Sharpeners

Understanding the Importance of Drill Bit Maintenance

Maintaining the sharpness of drill bits is crucial for achieving optimal performance in various drilling applications. A dull drill bit can lead to increased wear, reduced efficiency, and even damage to the material being drilled. By using a professional drill bit sharpener, you can extend the life of your drill bits and maintain their cutting edge.

Types of Drill Bits Requiring Sharpening

Drill bits made from high-speed steel, cobalt, masonry, and carbide all require regular sharpening to maintain their performance. Each type of drill bit has its unique characteristics and requires specific sharpening techniques to achieve the desired results.

Choosing the Right Drill Bit Sharpener

Key Features to Look For

When selecting a professional drill bit sharpener, consider the following features:

- Compatibility: Ensure the sharpener is compatible with the types of drill bits you use.

- Ease of use: A user-friendly design will make the sharpening process more efficient.

- Adjustability: Look for a sharpener that allows you to adjust the angle and depth of the grinding wheel.

- Durability: Invest in a high-quality sharpener that can withstand frequent use.

Comparing Cobalt & High-Speed Steel Drill Bit Sharpeners

Cobalt drill bits require a higher heat tolerance during sharpening compared to high-speed steel drill bits. Cobalt sharpeners are designed to handle the increased heat and maintain the integrity of the drill bit.

High-speed steel drill bits, on the other hand, require a more precise angle and depth setting to achieve optimal results. High-speed steel sharpeners are designed to provide accurate and consistent sharpening.

Masonry Drill Bit Sharpening Options

Masonry drill bits require a specialized sharpener designed to handle the unique characteristics of these drill bits. Masonry sharpeners typically feature a diamond grinding wheel that can withstand the abrasive nature of masonry materials.

How to Use a Professional Drill Bit Sharpener

Preparing Your Drill Bits for Sharpening

Before sharpening your drill bits, make sure they are clean and free of debris. Inspect the drill bit for any signs of damage or wear that may affect the sharpening process.

Step-by-Step Guide to Using a Drill Bit Sharpener

- Set up the sharpener: Adjust the angle and depth settings according to the type of drill bit being sharpened.

- Secure the drill bit: Hold the drill bit firmly in place using the sharpener's clamping mechanism.

- Start the sharpening process: Turn on the sharpener and slowly move the drill bit against the grinding wheel.

- Monitor the progress: Watch for signs of wear on the drill bit and adjust the angle and depth settings as needed.

- Stop the sharpening process: Once the desired sharpness is achieved, turn off the sharpener and remove the drill bit.

Maintaining Your Drill Bit Sharpener

Regular maintenance is essential to keep your drill bit sharpener in good working condition. Clean the sharpener after each use and inspect it for any signs of wear or damage. Replace worn parts as needed to ensure optimal performance.

Tips for Maximizing Drill Bit Performance

Proper Storage & Handling of Drill Bits

Store your drill bits in a dry, cool place away from moisture and extreme temperatures. Handle drill bits carefully to avoid damaging the cutting edge.

Identifying When to Sharpen Your Drill Bits

Signs that your drill bits require sharpening include increased wear, reduced efficiency, and difficulty drilling through materials. Regularly inspect your drill bits and sharpen them as needed to maintain their performance.

Troubleshooting Common Issues with Drill Bit Sharpeners

Common issues with drill bit sharpeners include misaligned angles, worn grinding wheels, and damaged clamping mechanisms. Address these issues promptly to ensure optimal performance.

By following these tips and using a professional drill bit sharpener, you can extend the life of your drill bits and maintain their cutting edge for optimal performance in various drilling applications.

Global Merch Park

Review

You May Also Like

6inch Aircraft Twisting Pliers: Aircraft Safety Wire Twister Electrical Lock Twisting Tool

Slip-Tooth Screw Pliers: A Comprehensive Guide

Large Size Plastic Face Washing Basin Thickened for Home Use Student Dormitory Use Small Basin for Washing Underwear And Feet

5/10m Reusable Cable Ties Freely Cut Lengths Hook Loop Self-Adhesive Fastener Tape Straps with 20 Buckles for Cable Organiser Velcro Cable Tie Wire Oragnizers Strong Adhesion Self Adhesive Fastener Cable Tie Straps Reusable Magic Hooks Loops Roll

Multifunctional Swords Display Rack Versatile Double Layer Swords Holder Sturdy Stand Rack for Trophies and Models

Efficient Replacement Bags Efficient Pool Vacuum Bags Cotton Texture for Home and Commercial Pools

Makita planer machine for wood 1400W plainer power tools wood

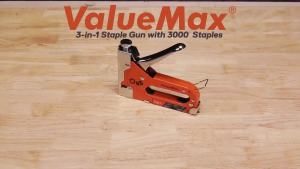

ValueMax Staple Heavy Duty 3-in-1 Manual Nail with 3000 Staples Upholstery Stapler for Wood Furniture Carpet Carpentry DIY Wire Decoration Craft Fixing Material Decoration

Floor Drain Odor Stopper Anti Odor Traps Toilet Inner Core Toilet Insect Repellent Sewer Pipe Sealing Closed Cover

EM-1166 & EM-1167 CARBON STEEL DAMAGE SCREW/ BOLT EXTRACTOR

Snap Button Pliers Set Metal Snap Button with Fastener Pliers Automatic Eyelet Puncher Set Snap Button Plier Tool