REAIM Cup Sealer Machine: Heavy Duty & Plastic Cup Sealing Solutions

REAIM Cup Sealer Machine: Heavy Duty & Plastic Cup Sealing Solutions

What is a Paper Cups Sealer?

A paper cups sealer, also known as a cup sealing machine, is a device designed to seal paper cups, plastic cups, and other disposable containers. This equipment plays a vital role in various industries, such as food service, beverage, and packaging. REAIM cup sealer machines are specifically designed to provide efficient sealing solutions for businesses.

How does a Paper Cups Sealer work?

A paper cups sealer machine operates by using heat and pressure to seal the cup's opening. This process ensures that the contents remain fresh and secure until the customer consumes them. REAIM cup sealer machines come in various models, including heavy-duty cup sealer machines and milk tea sealing machines, which cater to different business needs.

Benefits of using a Paper Cups Sealer

Using a paper cups sealer machine offers several advantages, including:

- Increased efficiency: REAIM cup sealer machines help businesses save time by automating the sealing process, allowing employees to focus on other tasks.

- Consistent quality: With precise temperature control and uniform pressure, these machines ensure consistent sealing results every time.

- Reduced waste: By providing reliable sealing solutions, businesses can minimize waste caused by improperly sealed cups.

- Enhanced customer satisfaction: Well-sealed cups contribute to a positive customer experience, as customers appreciate the attention to detail and care shown by businesses using high-quality equipment.

Choosing the Right Cup Sealing Machine

Selecting the appropriate cup sealing machine for your business requires careful consideration of several factors.

Factors to consider when selecting a Cup Sealing Machine

When choosing a cup sealing machine, keep the following points in mind:

- Capacity: Determine the number of cups you need to seal per day to ensure the machine meets your production requirements.

- Compatibility: Verify that the machine can accommodate various cup sizes and materials, including paper and plastic cups.

- Durability: Opt for a heavy-duty cup sealer machine built to withstand daily use and provide reliable performance.

- Ease of use: Select a machine with an intuitive interface and straightforward operation to minimize training time and reduce errors.

Comparing Heavy Duty Cup Sealer Machines

REAIM heavy-duty cup sealer machines stand out in the market due to their robust construction, advanced features, and competitive pricing. These machines offer superior performance compared to other heavy-duty cup sealer machines available in the market.

Maximizing Efficiency with a Milk Tea Sealing Machine

A milk tea sealing machine is specifically designed to meet the demands of the growing milk tea industry. These machines offer unique features tailored to the needs of milk tea shops and cafes.

Key features of a Milk Tea Sealing Machine

Some of the key features of a milk tea sealing machine include:

- Adjustable temperature control: Allows users to set the optimal temperature for sealing milk tea cups, ensuring consistent results.

- Quick changeover: Enables easy switching between different cup sizes and materials, reducing downtime during production.

- Compact design: Ideal for limited spaces, these machines fit seamlessly into any milk tea shop or cafe layout.

Tips for optimizing Milk Tea Sealing Machine performance

To maximize the efficiency of your milk tea sealing machine, follow these tips:

- Regularly clean and maintain the machine to ensure optimal performance.

- Train employees on proper machine operation to avoid mistakes and improve efficiency.

- Monitor the sealing process to identify potential issues early on and address them promptly.

Maintaining Your Cup Sealing Machine

Regular maintenance is essential to ensure the longevity and efficiency of your cup sealing machine.

Regular maintenance tasks for Cup Sealing Machines

Some routine maintenance tasks include:

- Cleaning the machine after each use to remove residue and debris.

- Inspecting the heating elements and replacing them if necessary.

- Lubricating moving parts to reduce wear and tear.

- Checking the machine's settings and adjusting them as needed.

Troubleshooting common issues with Cup Sealing Machines

Common problems with cup sealing machines may include uneven sealing, burnt cups, or machine malfunctions. To address these issues, refer to the machine's user manual or contact REAIM customer support for assistance.

Tool TECH Mall

You May Also Like

Kitchen Tool Tomato Scoop Vegetable Cup Drain Juice Avocado Seed Remover Fruit Divided Kitchen Gadget Tomato Digging Spoon

2025 New Christmas Ceramic Mugs Gift Box for Girls Company Gifts Christmas Eve Peaceful Night Water Cups Cartoon Design

ZYJC MALL Kids DIY Non-stick Half Round Tableware Dinnerware Rice Scooper Kitchen Utensil Soup Spoons Sushi Mold

Creative Rabbit Tray Silicone Mold Artistic Silicone Display Holder Mold For Making Playful Rabbit Trays Decoration

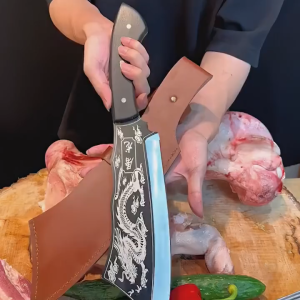

Mastering the Versatile Cutting Tool: Steel Bone-Chopping Knife & Japanese Dragon Knife

2-Tier Dish Drying Rack with Utensil Holder Stainless Steel Detachable Drain Bowl Large Capacity Black Finish

20 Pcs Round Mousse Cake Boards Food Grade Material For Cake Dessert

Chips and Salsa Serving Dish Reusable Chip and Dip Bowl Serving Dishes for Entertaining Plastic Dip Tray Plate with Dipping Sauce Compartment

Stainless Steel Rice Spoon Anti Scalding Cooker Scoop Multi-purpose Tableware Buffet Serving Spoons

Suomi 250ml 350ml 450ml Double Wall Transparent Glass Coffee Mug Heat Resitant Tea Mug Stripe Shape

Classy Luxe Kitchen Cabinet Storage Box Household Refrigerator Drawer Multifunctional Snack Organizer Box Sundries Storage Box