12V 24V Universal Fuel Transfer Pump, Electric Oil Pump, Micro Submersible Water Pump, Small Extraction Pump with 3m Pipe

12V 24V Universal Fuel Transfer Pump, Electric Oil Pump, Micro Submersible Water Pump, Small Extraction Pump with 3m Pipe

Introduction to Universal Fuel Transfer Pumps

What is a Universal Fuel Transfer Pump?

A universal fuel transfer pump is a versatile device designed to transfer fuel from one container to another. These pumps can be used in various applications, including boats, RVs, generators, and other vehicles that require fuel transfer.

12V & 24V Compatibility

Universal fuel transfer pumps are available in both 12V and 24V options, making them suitable for a wide range of applications. The voltage compatibility ensures that these pumps can be easily integrated into different systems, such as vehicles and generators.

Applications of Universal Fuel Transfer Pumps

Universal fuel transfer pumps have a broad range of applications, including transferring fuel from drums, tanks, and jerry cans. They are also useful for refueling boats, RVs, and generators. Additionally, these pumps can be used for transferring diesel, gasoline, kerosene, and other types of fuel.

Electric Oil Pumps Explained

How Electric Oil Pumps Work

Electric oil pumps are powered by electricity and are designed to circulate engine oil throughout the engine. These pumps help maintain proper lubrication, reduce wear and tear, and improve overall engine performance.

Benefits of Electric Oil Pumps

Some benefits of electric oil pumps include improved engine efficiency, reduced wear and tear, and increased fuel economy. Additionally, electric oil pumps can help extend the life of your engine by providing consistent lubrication.

Maintenance Tips for Electric Oil Pumps

To ensure optimal performance and longevity, it is essential to maintain electric oil pumps properly. This includes regularly checking the oil level, replacing the oil filter, and inspecting the pump for any signs of wear or damage.

3m Pipe Compatible Pumps

Why Choose a 3m Pipe Compatible Pump?

A 3m pipe compatible pump is designed to work with 3-meter-long pipes, making it ideal for transferring fluids over longer distances. These pumps are commonly used in various applications, including agriculture, construction, and industrial settings.

Installation Tips for 3m Pipe Compatible Pumps

When installing a 3m pipe compatible pump, it is essential to ensure that the pipes are securely connected and that there are no leaks. Additionally, it is important to check the pump's voltage and amperage requirements to ensure that it is compatible with your power source.

Common Issues & Solutions for 3m Pipe Compatible Pumps

Some common issues with 3m pipe compatible pumps include leaks, clogs, and electrical problems. To address these issues, it is essential to inspect the pump regularly and perform routine maintenance, such as cleaning the filter and checking for loose connections.

Micro Submersible Water Pumps

Advantages of Micro Submersible Water Pumps

Micro submersible water pumps are small, compact pumps designed to be submerged in water. These pumps are ideal for applications such as water wells, ponds, and aquariums. Some advantages of micro submersible water pumps include their compact size, high efficiency, and ease of installation.

How to Select the Right Micro Submersible Water Pump

When choosing a micro submersible water pump, it is important to consider factors such as the required flow rate, head height, and power source. Additionally, it is important to choose a pump that is compatible with your specific application and meets your performance requirements.

Maintenance Tips for Micro Submersible Water Pumps

To ensure optimal performance and longevity, it is essential to maintain micro submersible water pumps properly. This includes regularly cleaning the pump, checking for any signs of wear or damage, and replacing worn-out parts as needed.

Small Extraction Pumps

Applications of Small Extraction Pumps

Small extraction pumps are designed to extract fluids from small containers or tanks. These pumps are commonly used in various applications, including laboratory settings, automotive workshops, and industrial settings. Some common applications include extracting oil, coolant, and other fluids from vehicles and machinery.

Choosing the Right Small Extraction Pump

When choosing a small extraction pump, it is important to consider factors such as the required flow rate, head height, and power source. Additionally, it is important to choose a pump that is compatible with your specific application and meets your performance requirements.

Troubleshooting Common Issues with Small Extraction Pumps

Some common issues with small extraction pumps include leaks, clogs, and electrical problems. To address these issues, it is essential to inspect the pump regularly and perform routine maintenance, such as cleaning the filter and checking for loose connections.

HOMELNN

Review

You May Also Like

Black Fixed Length 2 In 1 Folding Guiding Rail Fiber Cable Stripper Fiber Optic Tools For Engineer

JMW-001 4-in-1 Round Shower Set: A Comprehensive Guide

Heavy Duty Hand Riveter Rivet Gun Riverting Tool Yellow Handle Fastener Household Tool Pop Rivet Gun Yellow Steel Iron Hand Riveter Blind Gun With Free 100pcs Nails

【Original+24hours delivery】Super steel Claw Hammer High toughness High hardness with magnetic attraction One-piece hand hammer Choice of stainless steel handle and fiber handle

Suction Cup Washbasin Hook Strong Wall-mounted Basin Hanger For Bathroom Storage Rack

8-28mm Wire Stripper Stripping Round Cable Insulation Cutter Plier Crimping Tool for Rubber Cable Electric Hand Tools

Brifit 130dB Personal Security Alarm Safety Key Buckle: Ideal Protection for Everyone

KKOLE Plain trolley or gate roller 0.5 ton 1 ton 2 ton

Wire Joining Tool: Pressure-Free Solder Ring, Quick Welding Connector, and Line Tube Terminal Plug-and-Play Wiring

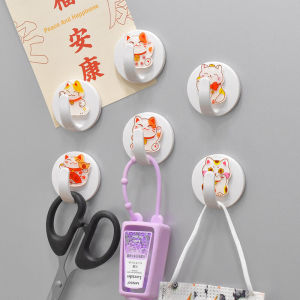

Strong Magnetic Kitchen Storage Hooks Fridge Magnets No Drilling Required Iron Absorption Non-Traceable Adhesive Hooks

Small Chain Wrench Quick Installation Pipe Fitting PE Water Pipe Tightening Chain Tube Wrench Hand Tool Cast Steel Manual