Jewelry Plating or Electroplating Machine 3A Silver Gold Plating Machine Voltage

Jewelry Plating or Electroplating Machine 3A Silver Gold Plating Machine Voltage

Introduction to Jewelry Plating Machines

Jewelry plating machines are essential tools used in the jewelry industry for coating metal surfaces with precious metals like gold and silver. This process enhances the appearance, durability, and value of jewelry pieces. In this article, we will explore the basics of jewelry plating, types of jewelry plating machines, and focus on the 3A plating machine, voltage plating machines, silver gold plating techniques, and electroplating machines.

Understanding the Basics of Jewelry Plating

Jewelry plating involves depositing a thin layer of metal onto a base material using various methods, such as electroplating, chemical plating, and physical vapor deposition. The primary goal is to improve the appearance and durability of jewelry pieces while reducing costs by using less expensive base materials.

Types of Jewelry Plating Machines

There are several types of jewelry plating machines available in the market, including:

- Electroplating machines: These machines use an electric current to deposit metal ions onto a base material.

- Chemical plating machines: These machines use chemical reactions to deposit metal ions onto a base material.

- Physical vapor deposition (PVD) machines: These machines use a vacuum chamber to deposit metal ions onto a base material.

Exploring the 3A Plating Machine

The 3A plating machine is a popular choice among jewelry manufacturers due to its versatility and efficiency. This section will discuss the key features of the 3A plating machine and how to use it effectively.

Key Features of the 3A Plating Machine

The 3A plating machine offers several advantages, including:

- High precision: The machine provides accurate and consistent plating results, ensuring uniform thickness and coverage.

- Energy efficiency: The machine consumes less energy compared to traditional plating methods, reducing operating costs.

- User-friendly interface: The machine features an intuitive control panel, making it easy to operate and maintain.

How to Use the 3A Plating Machine

Using the 3A plating machine is straightforward. Follow these steps to achieve optimal results:

- Prepare the jewelry pieces by cleaning and polishing them.

- Set up the plating solution according to the manufacturer's instructions.

- Place the jewelry pieces in the plating tank and connect the power supply.

- Adjust the voltage and current settings based on the desired plating thickness.

- Monitor the plating process and make adjustments as needed.

- Remove the jewelry pieces from the plating tank and rinse them thoroughly.

Voltage Plating Machine: An Overview

Voltage plating machines are essential tools for achieving precise and consistent plating results. This section will discuss voltage requirements for plating machines and the benefits of using voltage plating machines.

Voltage Requirements for Plating Machines

The voltage required for plating machines depends on several factors, including the type of metal being plated, the thickness of the plating layer, and the size of the jewelry pieces. Generally, lower voltages are used for thinner plating layers, while higher voltages are used for thicker plating layers.

Benefits of Voltage Plating Machines

Using voltage plating machines offers several advantages, including:

- Improved accuracy: Voltage plating machines provide precise control over the plating process, ensuring uniform thickness and coverage.

- Increased efficiency: Voltage plating machines can plate multiple jewelry pieces simultaneously, reducing production time and costs.

- Better quality: Voltage plating machines produce high-quality plating results, enhancing the appearance and durability of jewelry pieces.

Silver Gold Plating: Techniques & Applications

Silver gold plating is a popular technique used to enhance the appearance and value of jewelry pieces. This section will discuss common techniques for silver gold plating and its applications.

Common Techniques for Silver Gold Plating

There are several techniques used for silver gold plating, including:

- Electroplating: This method uses an electric current to deposit metal ions onto a base material.

- Chemical plating: This method uses chemical reactions to deposit metal ions onto a base material.

- Physical vapor deposition (PVD): This method uses a vacuum chamber to deposit metal ions onto a base material.

Applications of Silver Gold Plating

Silver gold plating has numerous applications in the jewelry industry, including:

- Enhancing appearance: Silver gold plating improves the appearance of jewelry pieces by giving them a luxurious finish.

- Increasing value: Silver gold plating adds value to jewelry pieces by enhancing their perceived worth.

- Improving durability: Silver gold plating increases the durability of jewelry pieces by protecting them from wear and tear.

Electroplating Machine: A Comprehensive Guide

Electroplating machines are essential tools used in the jewelry industry for coating metal surfaces with precious metals like gold and silver. This section will discuss how electroplating machines work and their advantages.

How Electroplating Machines Work

Electroplating machines use an electric current to deposit metal ions onto a base material. The process involves the following steps:

- Preparation: Jewelry pieces are cleaned and polished to remove any dirt or contaminants.

- Setting up the plating solution: A plating solution containing metal ions is prepared according to the manufacturer's instructions.

- Placing the jewelry pieces: Jewelry pieces are placed in the plating tank and connected to the power supply.

- Adjusting the voltage and current settings: Voltage and current settings are adjusted based on the desired plating thickness.

- Monitoring the plating process: The plating process is monitored and adjusted as needed.

- Removing the jewelry pieces: Jewelry pieces are removed from the plating tank and rinsed thoroughly.

Advantages of Electroplating Machines

Using electroplating machines offers several advantages, including:

- Improved accuracy: Electroplating machines provide precise control over the plating process, ensuring uniform thickness and coverage.

- Increased efficiency: Electroplating machines can plate multiple jewelry pieces simultaneously, reducing production time and costs.

- Better quality: Electroplating machines produce high-quality plating results, enhancing the appearance and durability of jewelry pieces.

LEOOYI Toys & Games

You May Also Like

Elegant Red Shark Clip Hair Accessories for Women Age Defying Deep Wine Red Large Hair Grips High End Feeling Hair Clips

Caile Crystal Earrings Star Moon Design Pendant Eardrop For Women Stud Trendy Dangle Earrings

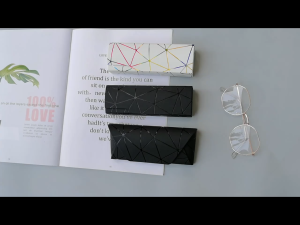

Lattice Dazzling Glasses Case Fashion Glasses Rigid Cover Fashion Glasses Case Protective Box

Fashionable Letter Pearl Brooch Pin for Women High End Elegant Diamond Pearl Chest Flower Suit Pin Anti-Light Exposure

Simulation Rose Hair Claw Clip for Girl Hair Clamps Spring Hair Style Tool PonytailHolder Hair Jaw Clip Hair Ornaments

Head Clip High Skull Top Bean Bag Updo Fixed Gadget Forehead Bangs Invisible Hairpin Female Head Fluffy Hair Comb Hairpin

Pt950 Plated Platinum Imitation D-Grade High Carbon Moissanite Ring Classic Micro-Inlaid Eight Hearts and Eight Arrows Six-Claw Ring for Women

Round Retro Women Dream Catcher Handmade Long Tassel Feather Earrings Female Leaves Pendant Earrings Boho

Pink Butterfly Knot Hair Clip Heavy Embellished Diamond Elegant New Style Fashionable Hair Accessories Fresh out Fresh Feeling

Tralyx Glasses for Riding Polarized Outdoor HD Sunglasses Night Vision Sports Bicycle Glass Mountain Bike Motorcycle

Gnker Brooch Set Big Beads Fashion Clothing Brooches for Women Pearl Lapel Pin Sweater Dress Brooch Pins Badge Buckle Diy Accessories