Micro Miniature Thrust Ball Bearings: A Comprehensive Guide

Micro Miniature Thrust Ball Bearings: A Comprehensive Guide

Introduction to Micro Miniature Thrust Ball Bearings

Micro miniature thrust ball bearings are a critical component in hardware tools and equipment, providing smooth operation and extended lifespan. This guide will help you understand the basics, key features, and applications of micro miniature thrust ball bearings, specifically focusing on inner diameters ranging from 2 to 12mm.

Understanding the Basics

Micro miniature thrust ball bearings are small-sized bearings designed to handle axial loads and provide rotational support for shafts and other components. They consist of inner and outer rings, balls, and a retainer, which holds the balls in place.

Key Features & Benefits

- Compact size: Micro miniature thrust ball bearings are ideal for applications where space is limited.

- High precision: These bearings are manufactured with tight tolerances, ensuring accurate and reliable performance.

- Low friction: The balls in these bearings roll smoothly, reducing wear and tear and extending the lifespan of the equipment.

Applications in Hardware Tools

Micro miniature thrust ball bearings are commonly used in hardware tools such as power drills, saws, and other handheld devices. They can also be found in various industrial equipment, medical devices, and precision instruments.

Choosing the Right Micro Miniature Thrust Ball Bearings

Selecting the appropriate micro miniature thrust ball bearing is crucial for optimal performance and longevity. Consider the following factors when choosing the right bearing:

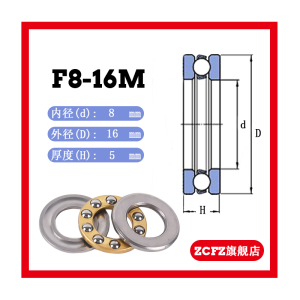

Selecting the Correct Inner Diameter (2-12mm)

The inner diameter of the bearing must match the shaft size. Common inner diameters range from 2 to 12mm, with increments of 1mm.

Considering Pressure Requirements

Determine the axial load capacity required for your application. This will help you select a bearing with the appropriate pressure rating.

Full Set Bearings for Optimal Performance

Using a full set of bearings, rather than individual components, ensures consistent performance and reduces the risk of misalignment or incorrect installation.

Using Micro Miniature Thrust Ball Bearings Effectively

To maximize the performance and lifespan of your micro miniature thrust ball bearings, follow these guidelines:

Installation Tips & Techniques

- Ensure proper alignment of the bearing with the shaft and housing.

- Use a press or suitable tool to install the bearing, avoiding direct hammering.

- Apply a thin layer of lubricant to the bearing and surrounding components.

Maintenance & Care

- Regularly inspect the bearing for signs of wear or damage.

- Clean the bearing and surrounding components with a suitable cleaning agent.

- Reapply lubricant as needed to maintain optimal performance.

Troubleshooting Common Issues

- Excessive noise: Check for misalignment, worn components, or insufficient lubrication.

- Premature wear: Ensure proper installation, alignment, and maintenance.

- Overheating: Verify adequate lubrication and cooling.

Conclusion

Micro miniature thrust ball bearings play a vital role in hardware tools and equipment, providing reliable performance and extended lifespan. By understanding the basics, selecting the right bearing, and using proper installation techniques, maintenance, and troubleshooting methods, you can ensure optimal performance and longevity for your micro miniature thrust ball bearings.

Recap of Key Points

- Micro miniature thrust ball bearings are essential components in hardware tools and equipment.

- Choose the correct inner diameter, pressure rating, and full set bearings for optimal performance.

- Follow installation tips, maintenance guidelines, and troubleshooting methods to maximize bearing lifespan.

Final Thoughts on Micro Miniature Thrust Ball Bearings

By understanding the importance of micro miniature thrust ball bearings and following the guidelines provided in this guide, you can ensure reliable performance and extended lifespan for your hardware tools and equipment. Remember to always prioritize safety and proper maintenance to protect your investment and maintain optimal performance.

TAO Home Tools

Review

You May Also Like

Wireless Portable Tire Inflator – Fast Inflation LED Display 150PSI para sa Kotse Motorcycle at Bisikleta!

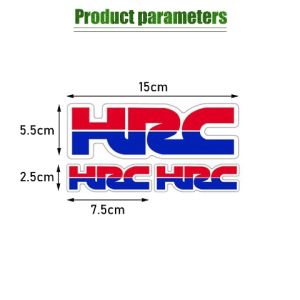

HRC Sticker for Honda wave click v3 pcx160 lead 125 vario Motorcycle Motorcycle Modified Stickers HRC Waterproof Reflective Dirt Bike Helmet Trunk Decorative Stickers PVC Decals

Torch Spark Plug F6T L7T E5T A5TC CM7H BM6A Gasoline Chainsaw Lawn Mower Motorcycle Ignition Plug

Vee Rubber VRM155 110/90- 13 TL 56LScooter Tire 110/90-13 TL (Tubeless)

MUTAKIN Racing Transmission Gear For Honda BEAT CARB

CYLINDER BLOCK SET YAMAHA FZ16 / SZ16 STD INDONESIA GENUINE PARTS 45P-E1310-00

Volkswagen One-Button Start Protection Cover CC Button Decorative Stickers for Lavida Sagitar Touran Yue Passat Car Accessories

【40% thicker】Exclusive universal car mitsubishi l300 steering wheel cover leather Fits 37-38cm/39-40cm steering wheel car buddy steering wheel cover universal steering wheel cover truck alcantara steering wheel cover vios steering wheel cover silicone

High Quality HKS Muffler Freeflow Free Flow-Medium Size(Intel: 2 In Outlet: 3.5 In)

VIC Fuel Filter F-197

Cute Bear Car Interior Decoration Panda Figurine Center Console Screen Placement Creative Decoration for Women in Cars