Ultra-Thin High-Purity Graphite Sheets: Custom Manufacturers Direct Sales

Ultra-Thin High-Purity Graphite Sheets: Custom Manufacturers Direct Sales

Introduction to Ultra-Thin Graphite Sheets

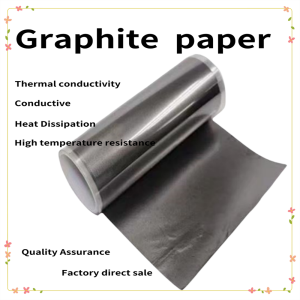

Ultra-thin graphite sheets, also known as high-purity carbon paper, have become increasingly popular due to their remarkable properties and wide range of applications. These sheets are available in various thicknesses, ranging from 0.05mm to 2mm, making them suitable for different industries and requirements.

Understanding 0.05-2mm Thickness

The 0.05-2mm thickness range allows for optimal flexibility and adaptability in various applications. This range ensures that the ultra-thin graphite sheets can be easily integrated into electronic devices, heat sinks, and other thermal management systems. Moreover, these sheets can withstand extreme temperatures and maintain their structural integrity, making them ideal for demanding environments.

Thermally Conductive Graphite Properties

Thermally conductive graphite is a type of high-purity carbon paper that exhibits excellent thermal conductivity. This property makes it an ideal choice for applications requiring efficient heat dissipation, such as in electronics, automotive, and aerospace industries. In addition to their thermal conductivity, these sheets also possess excellent electrical conductivity, which makes them suitable for use in various electronic components.

High-Purity Carbon Paper Applications

High-purity carbon paper finds extensive applications in industries such as electronics, automotive, aerospace, and renewable energy. Some common applications include:

- Heat sinks and thermal management systems

- Battery separators and electrode materials

- Electromagnetic shielding and EMI/RFI protection

- Solar panel substrates and interconnects

Custom Manufacturers Direct Sales

Dealing directly with custom manufacturers offers numerous advantages over purchasing from intermediaries. By working with direct suppliers, customers can enjoy better pricing, faster delivery times, and higher quality products.

Advantages of Direct Sales

Working directly with custom manufacturers offers several benefits:

- Competitive pricing: Direct sales eliminate the middleman, resulting in lower costs for customers.

- Customization options: Manufacturers can tailor their products to meet specific customer requirements.

- Faster delivery times: Direct sales enable quicker turnaround times, reducing lead times.

- Quality assurance: Direct manufacturers prioritize quality control to ensure customer satisfaction.

Quality Assurance from Custom Manufacturers

Custom manufacturers adhere to strict quality control measures to ensure that their products meet the highest standards. This includes rigorous testing, inspection, and certification processes to guarantee that each batch of ultra-thin graphite sheets meets the required specifications.

Ordering Process for Ultra-Thin Graphite Sheets

The ordering process for ultra-thin graphite sheets involves several steps:

- Contact the manufacturer to discuss your requirements and obtain a quote.

- Review the quotation and place your order if satisfied.

- Receive regular updates on production progress and shipping status.

- Inspect the delivered goods upon arrival to ensure they meet your expectations.

How to Use Ultra-Thin Graphite Sheets

To maximize the performance and longevity of ultra-thin graphite sheets, it is essential to follow proper installation, handling, maintenance, and troubleshooting procedures.

Installation and Handling Tips

When installing ultra-thin graphite sheets, keep the following tips in mind:

- Wear protective gloves and eyewear to avoid skin contact and eye irritation.

- Handle the sheets gently to prevent damage or tearing.

- Ensure proper alignment and secure attachment to prevent shifting or dislodging.

Maintenance and Cleaning Procedures

Regular cleaning and maintenance of ultra-thin graphite sheets can help extend their lifespan and maintain optimal performance. Follow these guidelines:

- Clean the sheets periodically using a soft cloth and mild detergent solution.

- Avoid using abrasive materials or harsh chemicals that may damage the surface.

- Store the sheets in a clean, dry environment away from direct sunlight and moisture.

Troubleshooting Common Issues

Some common issues that may arise when using ultra-thin graphite sheets include:

- Uneven thermal distribution: Ensure proper installation and alignment to avoid hot spots.

- Reduced thermal conductivity: Regular cleaning and maintenance can help maintain optimal performance.

- Physical damage: Handle the sheets gently and store them properly to prevent damage.

F S Shenzhen Huaqiang North Electronics City

Review

You May Also Like

Acrylic Enclosure Box Durability And Lightweighted For K2B Optimaled Protections And Heat Dissipation

for Key Lock Box Wall Mounted Portable Lock Box for House for Key Weatherproof Resettable Code for Outside Realtors Gara

MaxPlus Universal Car Nylon Cable Tie Buckle Black Self-Locking Plastic Wire Ties 20/50/100PCS

New Original Micro810 2080-LC10-12AWA 2080-LC10-12DWD 2080-LC10-12QBB 2080-LC10-12QWB

High Grade Primastic Holographic Rainbow Iridescenet Unicorn Hologram Pigment Color For Paint Binder or Powdercoat Juanderhues

Zamdon Toroidal Hybrid Off-grid Solar Inverter 48V6000W with 80A MPPT SCC

26MM Brushless Electric Hammer Electric Pick Impact Drill Multi-function Cordless Rotary Tool For Makita 18V Battery

【COD】1pcs Universal Triangle Support Furniture Corner Connector Frame Corner Bracket Stainless Steel Angle Fasten Screws【Including screws】

Gas pipe hose explosion-proof gas pipe natural gas liquefied gas gas stove gas tank connecting pipe

115-in-1 Magnetics Precision Screwdriver Set for iPhone & PC Repair

MECHANIC HD Visual Industrial Camera 8MP 1/1.8" CMOS Sensor with Real-Time Zero Delay Transmission & Ergonomic Wireless Control