MIG Welding Machine Inverter: A Comprehensive Guide

MIG Welding Machine Inverter: A Comprehensive Guide

What is a MIG Welding Machine Inverter?

MIG welding machine inverters are advanced welding tools that utilize IGBT technology to provide a portable, high-quality digital display welding experience. These machines are designed to offer superior performance, efficiency, and ease of use compared to traditional welding machines.

Understanding the Basics of MIG Welding

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a popular arc welding process that uses a consumable wire electrode and an inert gas to protect the weld pool from atmospheric contamination. MIG welding is widely used in various industries due to its speed, versatility, and ease of operation.

Key Features of a MIG Welding Machine Inverter

MIG welding machine inverters come with several key features that make them stand out:

- High-Quality Digital Display: A clear, easy-to-read digital display provides essential information about the welding process.

- IGBT Technology: Insulated Gate Bipolar Transistors (IGBTs) ensure efficient power conversion and precise control over the welding process.

- Portable Design: Compact and lightweight, these machines are easy to transport and use in various environments.

- Versatility: Many models, like the MIG-999, support MIG/MMA/TIG welding modes, allowing users to perform different types of welding tasks.

How Does a MIG Welding Machine Inverter Work?

A MIG welding machine inverter works by converting AC power into DC power using IGBT technology. This process allows for precise control over the welding current, voltage, and wire feed speed, resulting in a high-quality weld. The digital display provides real-time feedback, enabling users to adjust settings as needed.

Choosing the Right MIG Welding Machine Inverter

Selecting the perfect MIG welding machine inverter depends on several factors:

Factors to Consider When Selecting a MIG Welding Machine Inverter

- Power Requirements: Ensure the machine can handle the required power input, typically 220V.

- Welding Modes: Choose a machine that supports the desired welding modes, such as MIG/MMA/TIG.

- Portability: Consider the weight and size of the machine if you plan to use it in different locations.

- Budget: Determine your budget and find a machine that offers the best value for your needs.

Top MIG Welding Machine Inverter Models for Home Use

Some popular MIG welding machine inverter models for home use include:

- MIG-999: A high-quality, portable MIG/MMA/TIG welding machine with a digital display and IGBT technology.

- Model X: Another excellent choice for home users, offering similar features and performance.

MIG Welding Machine Inverter vs. Traditional Welding Machines

MIG welding machine inverters offer several advantages over traditional welding machines:

- Efficiency: IGBT technology ensures efficient power conversion, reducing energy consumption.

- Precision: Digital displays and precise control settings result in higher-quality welds.

- Portability: Compact design makes it easy to transport and use in various environments.

Setting Up Your MIG Welding Machine Inverter

Before starting a MIG welding project, ensure your workspace is properly prepared and your machine is assembled correctly.

Preparing Your Workspace for MIG Welding

- Clear the Area: Remove any flammable materials and ensure there is adequate ventilation.

- Protective Gear: Wear appropriate protective gear, including gloves, safety glasses, and a welding helmet.

- Grounding: Connect the grounding clamp to a clean, metal surface near the workpiece.

Assembling Your MIG Welding Machine Inverter

Follow the manufacturer's instructions to assemble your MIG welding machine inverter. Ensure all connections are secure and properly grounded before beginning the welding process.

Safety Precautions for MIG Welding

Always prioritize safety when working with MIG welding equipment:

- Read the Manual: Familiarize yourself with the machine's operating instructions and safety guidelines.

- Inspect Equipment: Regularly check for any signs of damage or wear on the machine and accessories.

- Follow Proper Techniques: Use proper welding techniques to avoid accidents and ensure high-quality results.

Using Your MIG Welding Machine Inverter

Mastering MIG welding techniques is essential for achieving successful results.

Basic MIG Welding Techniques

- Wire Feed Speed: Adjust the wire feed speed according to the material thickness and desired weld bead size.

- Voltage Settings: Set the voltage based on the material thickness and welding position.

- Travel Speed: Maintain a consistent travel speed to achieve a uniform weld bead.

Advanced MIG Welding Techniques

Once you've mastered the basics, explore more advanced techniques:

- Pulsed MIG Welding: Utilize pulsed MIG welding for thinner materials and improved control.

- Multi-pass Welding: Perform multiple passes to build up thicker welds and reduce distortion.

- Welding Positions: Practice welding in various positions, including flat, horizontal, vertical, and overhead.

Troubleshooting Common MIG Welding Problems

Encounter issues? Here are some common problems and solutions:

- Porosity: Ensure proper gas flow and adjust the wire feed speed.

- Undercutting: Increase the voltage and reduce the travel speed.

- Dross Formation: Decrease the voltage and increase the wire feed speed.

Maintaining Your MIG Welding Machine Inverter

Regular maintenance is crucial for extending the lifespan of your MIG welding machine inverter.

Cleaning and Maintenance Tips for MIG Welding Machine Inverters

- Clean the Nozzle: Remove any spatter or debris from the nozzle to maintain proper gas flow.

- Inspect the Wire Feeder: Check the wire feeder for any signs of wear or damage.

- Clean the Contact Tip: Replace the contact tip if it becomes worn or damaged.

Extending the Lifespan of Your MIG Welding Machine Inverter

By following proper maintenance procedures, you can extend the lifespan of your MIG welding machine inverter:

- Regular Inspections: Perform regular inspections to identify any issues early on.

- Replace Worn Parts: Replace any worn or damaged parts promptly.

- Store Properly: Store the machine in a clean, dry location when not in use.

When to Replace Parts of Your MIG Welding Machine Inverter

Replace parts when they show signs of wear or damage, such as:

- Contact Tip: Replace if it becomes worn or damaged.

- Nozzle: Replace if it becomes clogged or damaged.

- Wire Feeder: Replace if it shows signs of wear or damage.

Futengbao

Review

You May Also Like

Hardened White Steel Semi-Hollow Rivet Punch Manual Hammering Flipping Siding Bending Rivet Punch for Hardware And Tools

Digital Ultrasonic Cleaners: A Comprehensive Guide

Home Cleaning and Dredging Kit Rechargeable Drain Cleaner Home Cleaning and Dredging Kit Dirty Drainage Pipe Drilling Kit

2 in 1 Router Base Trimmers Router Tool Base Aluminum Palms Router Base Router Slotting Bracket for 65mm

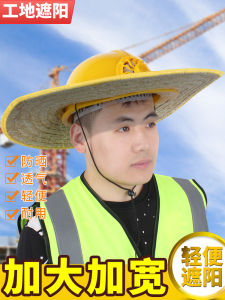

Safety Helmet Sun Protection Hat Brim Construction Site Sun Hat Workers Sun Protection Hat Construction Straw Hat Brim without Top Wheat Straw Neutral

(EM-987 EM-991EM-989) PVC WHITE Plastic faucet think and single cold rotable

DeLixi Wall-Mounted Clothes Hanger Strong Load Bearing Hook Entrance Hallway Hook No Drilling Required Space Saving Aluminum Hook

50/30/15 Meters Extension Wheel Cable Reel 220V Cord w/ HEAVY DUTY frame and SAFETY BREAKE COPPER

Wiping glass artifact glass wiper brush brush white cloud model glass cleaning water scraper single -sided rubbing window Glass Scraper Cleaner Soft Quality Plastic Glass Brush Wiper Floor Mirror Cleaning Brush

Makita 18V Cordless Drill Set – Compact High Power Brushless Includes 2 Batteries & Accessories

Heavy Duty Sliding Barn Door Hardware Track Kit Perf Carbon Steel Rustic Interior Sliding Wood Barn Door Hardware