Marine Bus Bar Terminal Studs: 250A 12V Terminal Block for Marine & RV Applications

Marine Bus Bar Terminal Studs: 250A 12V Terminal Block for Marine & RV Applications

Understanding Marine Electrical Accessories

Marine electrical accessories play a crucial role in ensuring reliable and efficient electrical systems in marine and recreational vehicles (RVs). One such accessory is the Marine Bus Bar Terminal Studs, which are designed to handle up to 250A at 12V DC voltage. These terminal blocks provide a secure and durable connection for wiring, allowing you to easily manage power distribution in your boat or RV.

What Are Marine Bus Bar Terminal Studs?

Marine bus bar terminal studs are robust connectors used to distribute electrical power from a single source to multiple devices or circuits. They consist of a sturdy block with multiple terminals, each capable of connecting a wire or cable. These terminal blocks are specifically designed for use in harsh marine environments, making them ideal for boats, yachts, and RVs.

Key Features of 12V Bus Bar Terminal Blocks

The 250A 12V bus bar terminal block offers several key features that make it an excellent choice for marine and RV applications:

- High current capacity: Designed to handle up to 250A at 12V DC voltage, ensuring reliable power distribution even under heavy loads.

- Weather-resistant construction: Made from durable materials, such as brass or copper, to withstand the harsh conditions commonly encountered in marine environments.

- Easy installation: Simple design allows for quick and straightforward installation, even for those with limited electrical experience.

- Versatile: Compatible with a wide range of wiring gauges, making it suitable for various marine and RV electrical systems.

How to Choose the Right Terminal Block for Your Needs

When selecting a marine bus bar terminal stud, consider the following factors to ensure it meets your specific requirements:

- Current capacity: Choose a terminal block with a current rating that matches or exceeds the maximum load of your electrical system.

- Voltage compatibility: Verify that the terminal block is designed for the voltage level of your electrical system (e.g., 12V DC).

- Material: Select a terminal block made from corrosion-resistant materials, such as brass or copper, to ensure long-term durability.

- Terminal count: Determine the number of terminals required based on the number of devices or circuits you need to connect.

Installation & Usage Tips

Proper installation and usage of marine bus bar terminal studs are essential for ensuring safe and efficient operation of your electrical system. Follow these guidelines to ensure optimal performance:

Preparing Your Marine or RV Electrical System

Before installing a marine bus bar terminal stud, take the following steps to prepare your electrical system:

- Identify the location: Choose a suitable location for the terminal block, taking into account the proximity to the power source and the devices or circuits it will connect.

- Gather necessary tools: Collect all required tools, such as wire strippers, crimping pliers, and screwdrivers.

- Inspect the wiring: Check the condition of the existing wiring and replace any damaged or worn-out cables.

Step-by-Step Installation Guide

Follow this step-by-step guide to install a marine bus bar terminal stud:

- Mount the terminal block: Secure the terminal block to the desired location using the provided mounting hardware.

- Strip the wires: Remove the insulation from the ends of the wires, exposing approximately 1/2 inch of bare conductor.

- Attach the wires: Insert the stripped wire ends into the appropriate terminals, ensuring a secure connection.

- Crimp the terminals: Use crimping pliers to attach the terminals to the wire ends, ensuring a tight and secure connection.

- Secure the connections: Tighten the screws on each terminal to ensure a firm grip on the wire ends.

- Test the connections: Verify that all connections are secure and functioning properly before powering up the system.

Troubleshooting Common Issues

If you encounter any issues with your marine bus bar terminal stud, refer to the following troubleshooting tips:

- Loose connections: Check that all wires are securely attached to the terminals and tighten any loose screws.

- Overheating: Ensure that the terminal block is rated for the current load and that the wiring is appropriate for the voltage level.

- Corrosion: Inspect the terminal block and wiring for signs of corrosion, and replace any affected components as needed.

Performance & Reliability

Using high-quality marine bus bar terminal studs can significantly improve the performance and reliability of your electrical system. Here are some benefits of using these terminal blocks:

Benefits of Using High-Quality Terminal Blocks

High-quality marine bus bar terminal studs offer several advantages over lower-grade alternatives:

- Enhanced durability: Made from corrosion-resistant materials, these terminal blocks can withstand harsh marine environments.

- Improved safety: Properly installed terminal blocks reduce the risk of electrical shorts and other hazards.

- Increased efficiency: Reliable connections ensure optimal power distribution, minimizing energy loss and improving overall system performance.

Ensuring Long-Term Durability

To ensure the long-term durability of your marine bus bar terminal studs, follow these maintenance tips:

- Regular inspections: Periodically check the terminal block and wiring for signs of wear or damage.

- Cleanliness: Keep the terminal block free of dirt, debris, and corrosion to maintain optimal performance.

- Proper storage: Store unused terminal blocks in a dry, cool location to prevent rust or corrosion.

Maximizing Efficiency in Marine & RV Applications

By using high-quality marine bus bar terminal studs and following proper installation and maintenance procedures, you can maximize the efficiency of your electrical system in marine and RV applications. These terminal blocks provide a reliable and durable solution for managing power distribution, ensuring safe and efficient operation of your boat or RV.

Toronto

Review

You May Also Like

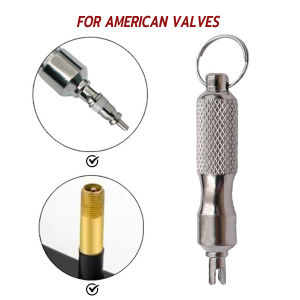

Tire Valve Core Screwdriver for Car Tyre Valve Core Remover Tool Tire Repair Keychain Design

T10 LED Park Lights & Waterproof Silicone Bulbs: A Comprehensive Guide

Honeycomb Hexagon Pattern Car Stickers Vinyl Decal Sticker Racing Car Body Side Sticker - 2 PCS (White)

ZEBRA 2023 Plain Full Face Dual Visor Helmet for Women with Silver Lens

Nissan Navara 2016 to 2025 INJECTION / OEM Type Window Door Rain Visor Black Thailand Quality ( Car Accessories )

quietness For 2023 MG 7 central control wireless charging silicone mat gear all-inclusive pad modification decoration supplies 3Y6W4S

Car Asphalt Renover 450ML Bug & Tar Remover Tar remover Car Degreaser General Purpose Cleaner Asphalt Remover One spray is ultra-clean and does not hurt the car paint

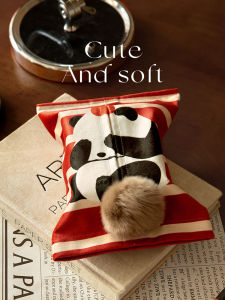

Full of Vitality Paper Cover Car Tissue Box Cute Panda Red Fabric Hanging Car Tissue Bag Buggy Bag

Rechargeable Car Sun Visor Mirror – Dimmable LED Night Driving & Day Vision Friendly

Heater Core Bypass Hose Coolant Crossover For 98-up GM Chevy Pontiac GEN 3 4 5 LSX LS1 LS2 LS3 LS6 LS7 LM7 LT1 LT4 LQ4 LQ9

Factory Direct Supply 0445120289 Common Rail Injector Assembly Full Models In Stock Brand New Injector Nozzle Injector