Air Compressor Bracket Assembly: Understanding Pressure Gauge Regulator & Automatic Switch

Air Compressor Bracket Assembly: Understanding Pressure Gauge Regulator & Automatic Switch

Introduction to Air Compressor Bracket Assembly

Air compressor bracket assemblies are essential components in air compressors, ensuring the proper functioning of pressure control systems. This article focuses on the Bama bracket assembly, a popular choice among professionals and DIY enthusiasts. The Bama bracket assembly includes a pressure gauge regulator, automatic pressure switch, and regulating valve assembly, all of which work together to provide efficient air pressure control.

Overview of the Product

The Bama bracket assembly is designed to work with air compressors that operate at a rated voltage of 220V and a max current of 20A. It features a normally closed contact method, with a bracket joint size of approximately 20mm / 0.8in. The outside diameter of the pressure relief port measures around 9.5mm / 0.4in. This assembly supports a working pressure range of 5-8Kg (90-120 PSI), with a switching pressure range of 0.5-0.8MPa (5-8Bar) (90-120PSI).

Key Features & Specifications

- Item Type: Air Compressor Bracket Assembly

- Rated Voltage: 220V

- Max Current: 20A

- Exhaust Pipe: Approx. 6mm / 0.2in

- Contact Method: Normally Closed

- Bracket Joint Size: Approx. 20mm / 0.8in

- Outside Diameter of Pressure Relief Port: Approx. 9.5mm / 0.4in

- Working Pressure: 5-8Kg (90-120 PSI)

- Switching Pressure Range: 0.5-0.8MPa (5-8Bar) (90-120PSI)

- Life: 80,000 times

- Material: Metal + Plastic

- Weight: Approx. 490g

- Max.Volt240-Amp.20-MaxBar12-PSI175

How to Install the Air Compressor Bracket Assembly

Installing the Bama bracket assembly requires a few simple steps. Follow this step-by-step guide to ensure a successful installation.

Step-by-step Installation Process

- Unpack the Bama bracket assembly and familiarize yourself with its components.

- Connect the exhaust pipe to the air compressor, ensuring a secure fit.

- Attach the bracket joint to the air compressor, aligning it with the desired position.

- Install the pressure relief port, ensuring it is properly connected to the assembly.

- Connect the pressure gauge regulator and automatic pressure switch to the assembly.

- Test the installation by turning on the air compressor and monitoring the pressure levels.

Tips for Successful Installation

- Make sure all connections are secure and properly aligned.

- Double-check the compatibility of the Bama bracket assembly with your air compressor model.

- Consult the manufacturer's instructions for specific installation guidelines.

Maintaining Your Air Compressor Bracket Assembly

Regular maintenance is essential to ensure the longevity and optimal performance of the Bama bracket assembly. Follow these tips to keep your air compressor bracket assembly in top condition.

Regular Maintenance Tips

- Inspect the connections for wear and tear, replacing any damaged components.

- Clean the exhaust pipe and pressure relief port regularly to prevent blockages.

- Lubricate moving parts as needed to reduce friction and prolong the life of the assembly.

Troubleshooting Common Issues

- If the air compressor fails to start, check the connections and ensure proper alignment.

- If the pressure levels fluctuate, adjust the pressure control settings or replace the pressure gauge regulator.

- If the automatic pressure switch malfunctions, consult the manufacturer's troubleshooting guide or contact customer support.

Enhancing Your Air Compressor Bracket Assembly Performance

Optimizing the pressure control settings and upgrading with Bama bracket accessories can help improve the overall performance of your air compressor bracket assembly.

Optimizing Pressure Control Settings

Adjust the pressure control settings according to your specific needs, taking into account the working pressure range and switching pressure range. Consult the manufacturer's instructions for guidance on adjusting these settings.

Upgrading with Bama Bracket Accessories

Consider upgrading your air compressor bracket assembly with Bama bracket accessories, such as additional pressure relief ports or enhanced pressure gauge regulators. These upgrades can help improve the efficiency and reliability of your air compressor system.

RICHARD DY

Review

You May Also Like

10PCS Stainless Steel Expansion Screws Carbon Steel Cross Flat Head Expansion Bolt for Concrete Wall Screws Fasteners Bolt

【In Stock】Cordless Impact Drill Concrete Impact Drill Rotary Drill Brushless 3 Systems Cordless Rotary Drill Electric Drill Brushless Motor Impact Drill Electric Hammer

10pcs Wall-Mounted Power Strip Holder Self-Adhesive Desktop Socket Fixer Strip Fixator Plug Socket Cable Wire Organizer Rack

86 Type Socket Protector Waterproof Double Socket Protector Electric Plug Cover Splash Box

Rayovac Hearing Aid Battery A13 (PR48) / A675 (PR44) 1.45V Zinc Battery

(Fast Delivery)10Pcs Car Motorcycle Repair Tool Box Hand Tools Set Socket Wrench Set

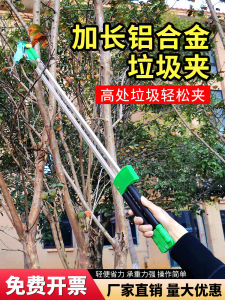

Aluminum Alloy Lightweight Extended Length Trash Grabber Clamp Household Cleaning Tool for

Mitsushi MIT-400NI mini Welding Machine Portable Sale with Digital Display IGBT Inverter Welding Machine Original Japan Welding Machine Set Weldind Rod Heavy Duty Welding Tools

Mobile Phone Remover Tool Eject Pins Needle Ejector with Anti Lost Case Removal Tool and Silicone Case

![[COD] shiou 70HF120 Spiral Rectifier Diode 1200V 70A 70HFR120 Blocking Diode Chassis Stud Mounting Replacement for Battery](https://img.lazcdn.com/g/p/a30490c7fa150fb09f861f4ebd09f1b2.jpg_300x300q80.jpg)

[COD] shiou 70HF120 Spiral Rectifier Diode 1200V 70A 70HFR120 Blocking Diode Chassis Stud Mounting Replacement for Battery

100/200Pcs Disposable Hairdressing Earmuffs Salon Clear Ear Cover Ear Protection Hair Dye Protect Cap Hair Color Styling Tool