Precision Trim Machine: A Comprehensive Guide

Precision Trim Machine: A Comprehensive Guide

Introduction to Double Head Trim Machines & Machine/Crown Fast Trim Machines

Precision trim machines have revolutionized the way professionals install crown molding and other decorative trims. Among these machines, double head trim machines and machine/crown fast trim machines stand out due to their efficiency, precision, and cost savings. In this comprehensive guide, we will explore the features, benefits, and usage of both types of machines, helping you make an informed decision about which one suits your needs best.

What is a Double Head Trim Machine?

A double head trim machine is a specialized tool designed to cut and install crown molding or other decorative trims. It features two cutting heads that work simultaneously, allowing for faster and more efficient installation compared to traditional methods. This type of machine is perfect for professionals who need to complete projects quickly and maintain a high level of quality.

What is a Machine/Crown Fast Trim Machine?

A machine/crown fast trim machine is another type of precision trim machine that combines cutting and installation functions. It is specifically designed for installing crown molding and other decorative trims. These machines offer enhanced precision and efficiency, making them ideal for professionals who want to save time and money while maintaining excellent results.

Benefits of Using a Machine/Crown Fast Trim Machine

Investing in a machine/crown fast trim machine can bring numerous benefits to your business. Here are some of the advantages:

Increased Efficiency

Machine/crown fast trim machines significantly increase efficiency by automating the cutting and installation process. This allows professionals to complete projects faster, reducing labor costs and increasing productivity.

Enhanced Precision

These machines offer enhanced precision, ensuring that every cut and installation is accurate and consistent. This results in a high-quality finish that meets the expectations of discerning clients.

Cost Savings

By investing in a machine/crown fast trim machine, professionals can save money on labor costs and reduce waste due to inaccurate cuts. Additionally, these machines often come with warranties and maintenance plans, providing long-term cost savings.

How to Choose the Right Machine/Crown Fast Trim Machine

When selecting a machine/crown fast trim machine, it's essential to consider several factors to ensure you make the right choice. Here are some key features to consider:

Key Features to Consider

- Cutting capacity: Ensure the machine can handle the size and thickness of the materials you work with.

- Precision: Look for machines with high accuracy and consistency in cutting and installation.

- Ease of use: Choose a machine that is easy to set up, operate, and maintain.

- Durability: Invest in a machine made from high-quality materials that can withstand heavy use.

- Customer support: Opt for brands that offer excellent customer support and maintenance plans.

Popular Brands & Models

Some popular brands and models of machine/crown fast trim machines include:

- TrimFast: Known for their precision and ease of use, TrimFast machines are a popular choice among professionals.

- CrownPro: These machines offer exceptional cutting capacity and durability, making them ideal for heavy-duty projects.

- TrimMaster: With a focus on accuracy and efficiency, TrimMaster machines are perfect for professionals who want to maintain a high level of quality.

Tips for Making an Informed Decision

- Research different brands and models before making a purchase.

- Read reviews and ask for recommendations from other professionals in your industry.

- Consider your budget and the features you need before making a decision.

How to Use a Machine/Crown Fast Trim Machine

Using a machine/crown fast trim machine is straightforward, but it's essential to follow the manufacturer's instructions to ensure optimal performance. Here's a step-by-step guide:

Setting Up Your Machine

- Unpack the machine and assemble it according to the manufacturer's instructions.

- Ensure all parts are securely attached and the cutting heads are aligned properly.

- Connect the power source and test the machine to ensure it's working correctly.

Operating the Machine

- Measure and mark the location where you want to install the crown molding or decorative trim.

- Adjust the cutting heads to the desired angle and depth.

- Turn on the machine and carefully guide it along the marked line.

- Install the trim using the provided fastening system.

Maintenance & Troubleshooting

- Regularly clean the machine to remove dust and debris.

- Lubricate moving parts to ensure smooth operation.

- Check for any signs of wear and tear and replace damaged parts as needed.

- Refer to the manufacturer's troubleshooting guide if you encounter any issues.

Conclusion: Why Every Professional Should Invest in a Machine/Crown Fast Trim Machine

Investing in a machine/crown fast trim machine is a smart decision for professionals who want to increase efficiency, enhance precision, and save money on labor costs. By choosing the right machine, setting it up correctly, and maintaining it properly, you can ensure that every project is completed to the highest standard. With the many benefits these machines offer, it's no wonder why they are becoming increasingly popular among professionals in the industry.

CROWN H. L. T. SEWINGMACHINE

Review

You May Also Like

zhaoyanping 1 Pcs Electric Hair Trimmer Clipper Replacement Power Switch Clipper Accessory Fit Most Hair Clipper

Portable Self-service Men Hair Clipper Professional Hair Clipper Mens Pocket Electric Hair Clipper

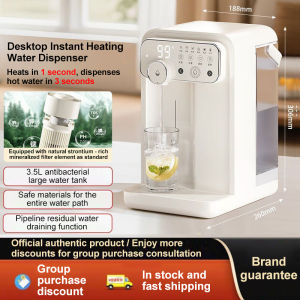

Xiaomi JMEY W3/Y3/G3 Instant Hot Water Dispenser Instant Hot Water Dispenser Home Desktop Water Dispenser Mini Portable Tea Making Bar One-button Intelligent Speed Heating 4-stage Water Temperature Electric Kettle Recommended By The Store Manager

【10 year warranty】3in1 Electric Hand Mixer Portable 5 Speed for Stirring Meat Dough Eggs (Hand Mixer Hand Mixer Electric Handheld Baking Hand Mixer)

Beiers No Added Sugar Ice Cream Powder Milk Shake Sugar Free Xylitol Home Use DIY Ice Cream Maker 375g from Liaoning China

High-End Eye Moisturizing Device Charging Model Relieves Eye Fatigue Steam Eye Massager Personal Care Health Massage Equipment

![[Buy 1 Take 1] 20000mAh Portable Waist Fan Clip on Wearable Belt Personal Fan Rechargeable Battery Operated Cooling Fan Hanging Neck Fan](https://img.lazcdn.com/g/ff/kf/Sa0d3019f10d446d798ec300ab450a86bJ.png_300x300q80.png)

[Buy 1 Take 1] 20000mAh Portable Waist Fan Clip on Wearable Belt Personal Fan Rechargeable Battery Operated Cooling Fan Hanging Neck Fan

Fityle Greek Yogurt Maker Stainless Steel Separator Reusable for Soybean Milk

Heavy Duty Blender Fruit Juicer Food Ice Crusher The Multifunctional Commercial Kitchen Appliances

Inverter Wall Fan: A Comprehensive Guide

Vacuum Thermal Cup for Women Large Capacity Insulated Straw Water Bottle Leak Proof Stainless Steel Drinkware