BIBLIO & NAU.K 50PCS Solder Seal Wire Connector: A Comprehensive Guide

BIBLIO & NAU.K 50PCS Solder Seal Wire Connector: A Comprehensive Guide

Introduction to Solder Seal Wire Connectors

Solder Seal Wire Connectors are essential components in electrical wiring applications, providing reliable connections and protecting wires from environmental damage. These connectors offer a simple one-step connection process that combines insulation welding and sealing, ensuring secure and robust connections.

What is a Solder Seal Wire Connector?

A Solder Seal Wire Connector is a type of electrical connector that utilizes a polyolefin tube on the outside and hot melt adhesive on the inside to achieve a welded seal. This design provides advanced waterproof performance, making it ideal for use in harsh environments.

Benefits of Using Solder Seal Wire Connectors

Using Solder Seal Wire Connectors offers several advantages, including:

- Simple one-step connection process

- Enhanced waterproof performance

- Increased pull-out strength

- Stress relief and cable inspection capabilities

- Reduced sparks connecting non-compliant wires

Waterproof Heat Shrink Terminal: A Closer Look

The waterproof heat shrink terminal is a crucial component of the Solder Seal Wire Connector. It consists of a polyolefin tube on the outside and hot melt adhesive on the inside, which provides advanced waterproof performance when heated.

Understanding Polyolefin Tube & Hot Melt Adhesive

Polyolefin tubes are made from a type of plastic that can withstand high temperatures and shrink when exposed to heat. Hot melt adhesive, on the other hand, melts when heated and then solidifies to form a strong bond between the wires and the connector.

Advanced Waterproof Performance

The combination of polyolefin tube and hot melt adhesive provides excellent waterproof performance, making the Solder Seal Wire Connector ideal for use in harsh environments. This advanced waterproof feature helps protect the wires from water damage and ensures reliable connections even in wet conditions.

Middle Connection Terminal Box & Heat Shrink Combination Box

The middle connection terminal box and heat shrink combination box are designed to enhance the pull-out strength and sealing capabilities of the Solder Seal Wire Connector. These components provide stress relief and cable inspection capabilities, ensuring a secure and reliable connection.

Enhancing Pull-Out Strength & Sealing

Polyolefin heat shrinkable butt connectors increase pull-out strength and provide sealing capabilities. This design helps prevent the wires from coming loose during use, ensuring a secure connection.

Stress Relief & Cable Inspection

The middle connection terminal box and heat shrink combination box provide stress relief and cable inspection capabilities. These features help protect the wires from damage and allow for easy inspection and maintenance of the connections.

IP67 Standard & Tubing

The Solder Seal Wire Connector meets the IP67 standard, which means it can withstand immersion in water up to 1 meter deep for up to 30 minutes. This high level of protection ensures reliable connections even in harsh environments.

Reducing Sparks Connecting Non-Compliant Wires

The tubing used in the Solder Seal Wire Connector reduces sparks connecting non-compliant wires. This feature helps prevent electrical fires and ensures safe connections.

Ensuring Strong Holding & No Slippage

When heated, the tubing used in the Solder Seal Wire Connector reduces in size and solder will melt and flow through the stripped wires, ensuring strong holding and preventing slippage. This design helps ensure a secure and reliable connection, even in harsh environments.

Biblio

Review

You May Also Like

Huepar 2-in-1 Laser Tape Measure: A Comprehensive Guide

Square Tube Pipe Connector For 25mmx25mm Stainless Steel Tube Pipe Square Tube Flange DIY Clothes Rack Cabinet Frame Accessories

Original Pro’skit Soldering Trumpet High Temperature Resistant Solder Flux Vacuum Pump Sweeping Tool Electronic Repair Kit

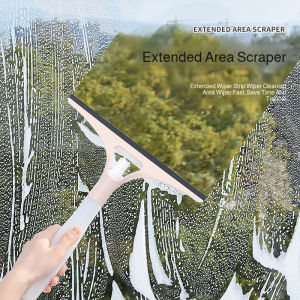

Multifunctional Glass Wiper Spray Cleaning Brush Removable Bathroom Glass Wiper With Sprayer

Extra-long Plug-in Strip 5M/10M/20M Electric Vehicle Charging Extension Cordsocket

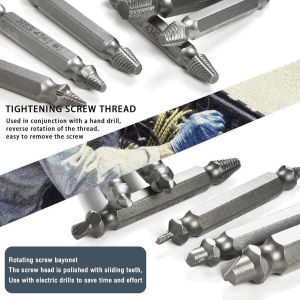

ZEO 5Pcs/set Damaged Screw Extractor Remover for Stripped Head Screws Nuts & Bolts Drill Bit Tools

Ecoco Bathroom Mop Holder: A Strong Adhesive Stick-on Rack Hook & Wall-Mounted Cleaning Tool

Black And White Picture Frame Hooks Hardware Accessories Decorative Painting Advertising Board Four Hole Dark Hanging Hardware Wall Hooks 100 Pieces

Pipe Dredging Agent Powerful Clog Remover Drainage Clog Remover Pipe Cleaner Clogged Drain Remover Toilet Bowl Sink Remover Drain Cleaner Dissolves Grease Hair Oil Organic Wastes and Food Residue Multipurpose Clog Remover for Pipes

Professional Leather Repair Paste Filler Kit for Scratches Cuts & Holes Car Seat Sofa Furniture Restoration Permanent Paste

COD Stainless Steel Hinge Repair Plate Cabinet Door Repair Plate Fixed Installation Plate w/Screws