Soldering Lead 0.8: A Comprehensive Guide

Soldering Lead 0.8: A Comprehensive Guide

Introduction to Soldering Lead 0.8

Soldering lead is a critical component in the world of electronics, used to join electrical components and form secure connections. This guide will focus on the ICHIBAN soldering lead 0.8m/m, a high-quality product from Nippon Kwzoku Kogyosho Co. Ltd. in Osaka, Japan. The soldering lead comes in a roll and features a 60/40 composition, making it ideal for various applications.

What is Soldering Lead?

Soldering lead is a metal alloy used to join electrical components, forming a strong and reliable connection. It typically consists of tin and lead, with varying ratios depending on the specific application.

Types of Soldering Lead

Soldering lead comes in various compositions, such as 60/40, 63/37, and 50/50, referring to the ratio of tin to lead. Each type has unique properties and is suited for different applications.

Why Choose Soldering Lead 0.8m/m?

The ICHIBAN soldering lead 0.8m/m offers a cost-effective solution with high-quality performance and long-term reliability. Its 60/40 composition makes it ideal for various electronic applications, and its 0.8m/m diameter ensures precise soldering.

Key Features of ICHIBAN Soldering Lead 0.8m/m

Brand Background: Nippon Kwzoku Kogyosho Co. Ltd.

ICHIBAN soldering lead is manufactured by Nippon Kwzoku Kogyosho Co. Ltd., a reputable company based in Osaka, Japan. With a strong reputation for quality and reliability, ICHIBAN soldering lead is trusted by professionals worldwide.

Composition: 60/40 Soldering Lead

The ICHIBAN soldering lead 0.8m/m features a 60/40 composition, consisting of 60% tin and 40% lead. This ratio provides excellent wetting properties, ensuring a strong bond between components.

Quality Assurance

ICHIBAN soldering lead undergoes rigorous testing and quality control measures to ensure its reliability and consistency. This commitment to quality makes it a preferred choice among professionals.

How to Use Soldering Lead 0.8m/m

Preparation Before Using Soldering Lead

Before using the ICHIBAN soldering lead 0.8m/m, ensure that your workspace is clean and free of debris. Gather all necessary tools, such as a soldering iron, flux, and wire cutters. Proper preparation will help you achieve optimal results.

Step-by-Step Soldering Process

- Heat up the soldering iron and apply flux to the components to be joined.

- Feed the soldering lead into the joint, allowing it to melt and flow around the components.

- Remove the soldering iron and allow the joint to cool and solidify.

- Trim excess solder with wire cutters, if necessary.

Troubleshooting Common Issues

- Cold joints: Ensure the soldering iron is hot enough before applying solder.

- Excess solder: Use wire cutters to trim away excess solder after the joint has cooled.

- Poor wetting: Apply more flux to improve the solder's flow.

Benefits of Using Soldering Lead 0.8m/m

Cost-Effective Solution

The ICHIBAN soldering lead 0.8m/m offers a cost-effective solution for professionals and hobbyists alike. Its high-quality performance and long-term reliability make it a worthwhile investment.

High-Quality Performance

With its 60/40 composition and rigorous quality control measures, the ICHIBAN soldering lead 0.8m/m delivers exceptional performance in various electronic applications.

Long-Term Reliability

ICHIBAN soldering lead is designed to withstand the rigors of daily use, ensuring long-term reliability and durability. This makes it a preferred choice among professionals who value quality and consistency.

tssh

Review

You May Also Like

LO-201/LO-202/LO-203 16A 250V TWO WAY SHADOW GRAY ELECTRICAL OUTLET

CHERRY BLOSSOM: 100g/300g Sealant Waterproof Glue & Invisible Paste

Transparent Waterproof Glue: 50 Years Without Water Leakage

Ecoco Anti-odor Anti-Insect For Bathroom Gasket Sealing Cover Silicone Floor Drain

200 Degree Door Viewer Peephole Adjustable With Cover Wide Angle Cat Eye

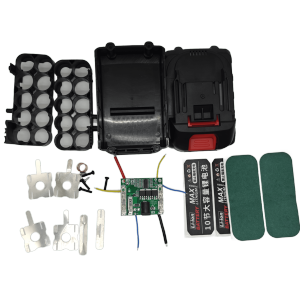

18V 21V Screwdriver Battery Case 5X 10X 15X 18650 Holder 5S 50A Bms Welding Nickel Suitable for 6Ah to 14Ah Electric Drill Use

Chainsaw Sharpener Jig: A Comprehensive Guide

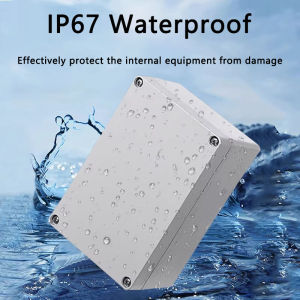

IP67 Waterproof Junction Box Outdoor Aluminum Enclosure Industry PCB Project Instrument Case Explosion-Proof Electronics Housing

Gas Cylinder Liquefied Gas Flashback Arrestor Oxygen Acetylene Anti-Tempering Valve Propane Natural Gas Bottle Bellows Device

Portable Electric Drill Pump: High Performance Transfer Pump & Oil Fluid Water Pump

Oil Proof Wallpaper PVC material Kitchen table wall film Electrostatic adsorption Protection Film Home decorate