All Bronze Gas Torch Welding Nozzle Heat Flame Gun Bronze Brazing Blow Torch Propane Gas

All Bronze Gas Torch Welding Nozzle Heat Flame Gun Bronze Brazing Blow Torch Propane Gas

Introduction to Bronze Gas Torch Welding Nozzles

Bronze gas torch welding nozzles are essential tools used in various welding applications. They are designed to provide precise control over the flame, allowing for accurate and efficient brazing, soldering, and other thermal processes. This article will delve into the details of bronze gas torch welding nozzles, their types, benefits, and how to choose the right one for your needs.

What is a Bronze Gas Torch Welding Nozzle?

A bronze gas torch welding nozzle is a component of a gas torch system that controls the flow of gas and air mixture, producing a flame suitable for welding, brazing, and soldering. The nozzle is typically made of bronze, which is a durable and heat-resistant material, ensuring long-lasting performance.

Types of Bronze Gas Torch Welding Nozzles

There are various types of bronze gas torch welding nozzles available, including:

- Straight nozzle: Ideal for general-purpose welding and brazing applications.

- Conical nozzle: Provides a wider flame pattern, suitable for larger workpieces.

- Swirl nozzle: Creates a swirling flame pattern, which helps in achieving better heat distribution.

Benefits of Using a Bronze Gas Torch Welding Nozzle

Using a bronze gas torch welding nozzle offers several advantages:

- Precision: Provides accurate control over the flame, allowing for precise welding and brazing.

- Efficiency: Ensures efficient use of fuel, reducing waste and lowering costs.

- Durability: Made from bronze, a heat-resistant material, ensuring long-lasting performance.

Choosing the Right Bronze Gas Torch Welding Nozzle

Selecting the appropriate bronze gas torch welding nozzle depends on various factors, including the type of workpiece, the desired flame pattern, and the required level of precision. Here are some key considerations:

Factors to Consider When Selecting a Bronze Gas Torch Welding Nozzle

- Type of workpiece: Consider the size, shape, and material of the workpiece to determine the appropriate nozzle type.

- Flame pattern: Choose a nozzle that produces the desired flame pattern for optimal results.

- Precision: Select a nozzle that offers the required level of precision for your welding or brazing application.

How to Choose the Best Bronze Gas Torch Welding Nozzle for Your Needs

To select the best bronze gas torch welding nozzle, consider the following steps:

- Identify the type of workpiece and the required flame pattern.

- Evaluate the precision needed for your application.

- Compare different nozzle types and their features.

- Choose the nozzle that best meets your requirements.

Long-Term Maintenance and Care for Your Bronze Gas Torch Welding Nozzle

To ensure the longevity and optimal performance of your bronze gas torch welding nozzle, follow these maintenance tips:

- Clean the nozzle regularly to remove any debris or residue.

- Inspect the nozzle for signs of wear or damage.

- Replace the nozzle if necessary to maintain proper flame control.

Using a Bronze Gas Torch Welding Nozzle

Operating a bronze gas torch welding nozzle safely and effectively requires proper technique and attention to detail. Here are some essential guidelines:

How to Safely Operate a Bronze Gas Torch Welding Nozzle

- Follow the manufacturer's instructions for safe operation.

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation to avoid inhaling harmful fumes.

- Maintain a safe distance from flammable materials.

Common Applications for Bronze Gas Torch Welding Nozzles

Bronze gas torch welding nozzles are commonly used in various applications, including:

- Brazing: Joining two metals using a filler material with a lower melting point than the base metals.

- Soldering: Joining two metals using a filler material with a lower melting point than the base metals.

- Welding: Fusing two metals together using heat and pressure.

Tips for Getting the Most Out of Your Bronze Gas Torch Welding Nozzle

To maximize the performance of your bronze gas torch welding nozzle, consider these tips:

- Practice proper technique to achieve consistent results.

- Regularly clean and inspect the nozzle to ensure optimal performance.

- Replace the nozzle if necessary to maintain proper flame control.

Frequently Asked Questions About Bronze Gas Torch Welding Nozzles

What Are the Differences Between a Brazing Blow Torch and a Gas Torch for Brazing?

A brazing blow torch is a handheld tool used for brazing applications, while a gas torch for brazing is a more versatile tool that can be used for various welding and brazing applications. A brazing blow torch typically has a simpler design and is easier to operate, making it ideal for beginners.

What Are the Differences Between a Heat Gun for Welding and a Propane Flame Gun?

A heat gun for welding is a tool used to generate high temperatures for welding applications, while a propane flame gun is a tool used to produce a flame for welding, brazing, and soldering applications. A heat gun typically has a higher temperature range and is more suitable for precision welding applications, while a propane flame gun is more versatile and can be used for various thermal processes.

What Are the Differences Between a Bronze Gas Welding Nozzle and a Propane Brazing Blow Torch?

A bronze gas welding nozzle is a component of a gas torch system used for welding and brazing applications, while a propane brazing blow torch is a handheld tool used for brazing applications. A bronze gas welding nozzle provides precise control over the flame, while a propane brazing blow torch is easier to operate and ideal for beginners.

CPS HARDWARE

You May Also Like

Professional Silicone Welding Station Helper For LED Capacitors Resistors Secure Grip And Component Organization

Rabbitfix Grinding Needle 0.3mm/0.4mm Ultra-fine High Hardness Ball Needle 2.35mm Engraving Mobile Phone Repair Tool

5in1 Silicone Scraper Angle Beauty Crack Trowel Squeegee Glue Remover Caulking Grout Scraper Kit Multifunctional Home Tool

Long Sleeve Covers for Women: 2024 New Autumn Winter Office Work Durable Dirty Proof Protective Sleeves for Down Jacket

21V Batteries for Pressure Gun Car Washer Sprayer Battery Super Endurance Battery Electric Drill Bat

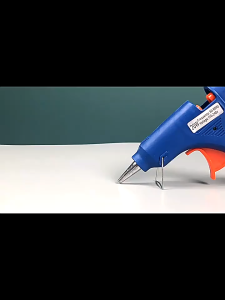

20W 110-240V Hot Melt Glue Gun Glue Gun Heavy Duty Electric Heating Melt Glue Gun Hot Melt Glue Sticks Prevent Burns Safety

Jozoo Long-Handled Toilet Brush Curved Head Soft Bristles Quick Drying Bathroom Corner Cleaning Tools

(2 Pieces) Art Roller - Essential Craft Tool for Rhinestone Embroidery Easy-Grip Hand Roller Detachable Painting Tool

230*14cm Concave/Convex Corner Foam Wall Edge Strips Self-adhesive Wall Decor Top Angle Line Sticker

COD Automatic Booster Pump Connector Housing 24V 120W 75 feet Pressure Water Pump for kitchen Sink Shower Head Outside Tap

1pcs 30 X 30CM Modern Kitchen Bathroom 3D Tiles Wall Sticker Waterproof Self Adhesive Wallpaper Bedroom PVC Home Decor