Commonly Used Width 6.4/10/12/16/19/25mm Electrostatic SS 304 Stainless Steel Cable Tie Band

Commonly Used Width 6.4/10/12/16/19/25mm Electrostatic SS 304 Stainless Steel Cable Tie Band

Introduction to Narrow Band Cable Ties & Electrostatic Cable Strapping

Narrow band cable ties and electrostatic cable strapping are essential components in various industries, providing secure and reliable fastening solutions. These cable ties are made from high-quality, real SUS 304 stainless steel, offering superior durability and corrosion resistance.

Key Features of Real SUS 304 Stainless Steel Cable Ties

Real SUS 304 stainless steel cable ties offer several key features:

- Corrosion Resistance: Resistant to rust and corrosion, ensuring long-lasting performance in harsh environments.

- High Strength: Strong and robust, capable of securely fastening heavy loads.

- Temperature Range: Can withstand temperatures ranging from -80°C to +540°C, making them suitable for extreme conditions.

- Versatility: Available in various widths, catering to different applications and requirements.

Overview of Commonly Used Widths: 6.4/10/12/16/19/25mm

Real SUS 304 stainless steel cable ties come in six commonly used widths: 6.4mm (1/4"), 10mm (3/8"), 12mm (1/2"), 16mm (5/8"), 19mm (3/4"), and 25mm. Each width caters to specific applications and load capacities, ensuring optimal performance.

High Standard Cable Tie Applications & Benefits

High standard cable ties have numerous applications across various industries, including solar systems, pipes, mines, ships, electricity, electric boxes, and sign boards. These cable ties offer several benefits:

- Durability: Withstands harsh environmental conditions, ensuring long-lasting performance.

- Reliability: Provides secure fastening solutions, reducing the risk of cable failure.

- Cost-Effective: Reduces maintenance costs by minimizing the need for frequent replacements.

- Versatility: Suitable for a wide range of applications, catering to different industries and requirements.

Industrial Applications: Solar Systems, Pipes, Mines, Ships, Electricity, Electric Boxes, Sign Boards

High standard cable ties find application in various industries, including solar systems, pipes, mines, ships, electricity, electric boxes, and sign boards. These cable ties offer reliable and secure fastening solutions, ensuring optimal performance in these demanding environments.

Temperature Range: -80°C to +540°C

Real SUS 304 stainless steel cable ties can withstand temperatures ranging from -80°C to +540°C, making them suitable for extreme conditions. This wide temperature range ensures reliable performance in various industrial applications.

Wholesale Cable Strapping Options

Wholesale cable strapping options are available for real SUS 304 stainless steel cable tie bands. These options cater to large-scale industrial applications, offering cost-effective solutions for securing cables and wires.

Manufacturers & Suppliers of Electrostatic SS 304 Stainless Steel Cable Tie Bands

Several manufacturers and suppliers offer electrostatic SS 304 stainless steel cable tie bands. These companies specialize in producing high-quality cable ties, ensuring optimal performance and reliability.

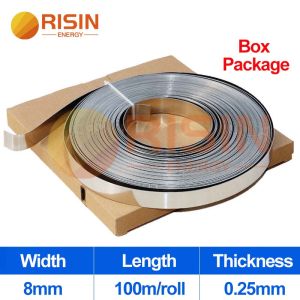

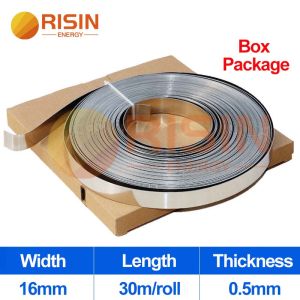

Risin Stainless Steel Banding Strapping Narrow Band Cable Ties

Risin is a leading manufacturer of stainless steel banding strapping narrow band cable ties. These cable ties offer superior performance, durability, and reliability, making them ideal for various industrial applications.

Tips for Using High Standard Cable Ties

Using high standard cable ties requires proper installation techniques and regular maintenance to ensure optimal performance and longevity.

Proper Installation Techniques

To ensure optimal performance, follow these installation techniques:

- Select the appropriate width: Choose the correct width based on the load capacity and application requirements.

- Securely fasten the cable tie: Tighten the cable tie to ensure a secure fit, avoiding any slack or loose ends.

- Use appropriate tools: Use the correct tools for installation, such as pliers or cutters.

Maintenance & Longevity of Narrow Band Cable Ties

Regular maintenance is essential to ensure the longevity of narrow band cable ties. Follow these tips:

- Inspect regularly: Regularly inspect the cable ties for any signs of wear or damage.

- Clean and lubricate: Clean the cable ties and apply lubrication to prevent rust and corrosion.

- Replace as needed: Replace any damaged or worn-out cable ties to maintain optimal performance.

Risin Energy Onestop

Review

You May Also Like

HENKEL SISTA D100 PLUS ACRYLIC WATERPROOFER AND SEALER WATERPROOFING GERMANY QUALITY WATER BASED LITER GALLON

NG Motor✨ COD ✨ Car BTS7960 43A Double H-bridge High-Power Driver Module DIY Smart Car Current Diagnostic For Arduino

aiqinhaimaoyi For Alloy Guitar Strings DIY Assorted File Cylindrical File Dia 1 1.2 1.5 1.7 2.2 2.8 3.3 4 5 6mm Grinding Tool

10PCS Original Impact Socket Set 1/2 Drive Hex 8-24mm For Wrench Adapter Spanner Deep Socket Key Impact Socket Long Pneumatic Wrench Head Mechanical Workshop Tools Garage

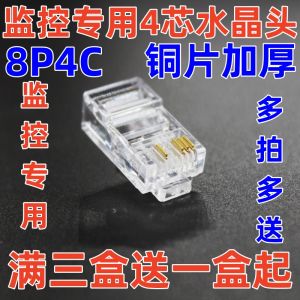

Pure Copper Gold-Plated Network Modular Plug RJ45 Ultra-Class 5 Unshielded 8-Core Network Cable Ultra-Class 6 Shielded Cable Connector

Pressurized shower head for home bathroom shower suit - water heater rain shower head Shower head

Solar Inverter 150w 250w 300w 500W Solar Power Supply Inverter 12V DC/230V AC Output Max Inverter

Stainless Wet Film Thickness Gauge 25-3000um Hexagon High Precision Steel Wet Film Comb Wet Film Gauge

![[Dale Dephne] Micro N20 Gear Motor Slow Speed Metal Gearbox Reducer Electric Motor DIY Toy](https://img.lazcdn.com/g/p/bb67c5bd6d7addd12651f6b00ce718dd.jpg_300x300q80.jpg)

[Dale Dephne] Micro N20 Gear Motor Slow Speed Metal Gearbox Reducer Electric Motor DIY Toy

JOUST MAX TCT SAW BLADE: Maximize Your Woodworking Performance

(Fast Delivery) 6Pcs Step Drill Bit Saw Drill Bit Set Titanium Milling Cutter 4-12 4-20 4-32mm 3 6 8mm For Woodworking Metal Core Hole Opener