Liquid Level Control Switch ST-2000AB Float Switch

Liquid Level Control Switch ST-2000AB Float Switch

What is Industrial Liquid Level Control?

Industrial liquid level control refers to the monitoring and regulation of fluid levels within tanks, reservoirs, or vessels in industrial settings. By ensuring precise control over fluid levels, industrial liquid level control systems contribute to efficient operations, safety, and cost savings.

Key Components of Liquid Level Control Systems

Liquid level control systems consist of several components, including sensors, switches, controllers, and actuators. These components work together to monitor fluid levels, send signals to control devices, and adjust fluid flow accordingly.

Benefits of Using Liquid Level Control Switches

Liquid level control switches, such as the ST-2000AB float switch, offer numerous benefits, including:

- Enhanced safety: Prevent overfilling or underfilling of tanks, reducing the risk of spills, fires, or other hazards.

- Increased efficiency: Automate fluid level monitoring and control, minimizing manual intervention and human error.

- Cost savings: Optimize fluid usage, reduce waste, and lower maintenance costs.

How to Choose the Right Float Switch for Your Water Tank

Selecting the appropriate float switch for your water tank is crucial for effective liquid level control. Consider the following factors when choosing a float switch:

- Tank size and shape: Ensure the float switch is compatible with your tank dimensions and geometry.

- Fluid properties: Consider the viscosity, density, and corrosiveness of the fluid being monitored.

- Operating temperature range: Verify that the float switch can withstand the expected temperature fluctuations.

- Mounting options: Select a float switch with mounting options that suit your tank design.

Comparing ST-2000AB Float Switch with Other Options

The ST-2000AB float switch offers several advantages over other float switches, including:

- Robust construction: Durable materials and design ensure reliable performance in harsh environments.

- Wide operating temperature range: Suitable for both hot and cold fluids.

- Versatile mounting options: Compatible with various tank configurations.

- Cost-effective: Competitive pricing without compromising on quality.

Installation & Maintenance Tips for ST-2000AB Float Switch

To ensure optimal performance and longevity of the ST-2000AB float switch, follow these installation and maintenance guidelines:

Steps to Install ST-2000AB Float Switch

- Select the appropriate mounting option: Choose the correct mounting bracket or flange for your tank.

- Position the float switch: Ensure the float switch is centered within the tank and positioned at the desired liquid level.

- Secure the mounting hardware: Tighten all screws and bolts to prevent movement during operation.

- Connect electrical wiring: Follow manufacturer instructions for connecting power and control wires.

Best Practices for Maintaining ST-2000AB Float Switch

- Regular cleaning: Remove any debris or buildup from the float switch and surrounding area.

- Inspect for damage: Check for signs of wear or corrosion on the float switch and replace if necessary.

- Calibrate regularly: Verify the accuracy of the float switch and adjust settings as needed.

Troubleshooting Common Issues with ST-2000AB Float Switch

Despite proper installation and maintenance, issues may arise with the ST-2000AB float switch. Follow these troubleshooting tips to identify and resolve common problems:

Identifying and Fixing Malfunctions

- Float switch fails to activate: Check for obstructions, ensure proper positioning, and verify electrical connections.

- Inaccurate readings: Calibrate the float switch according to manufacturer instructions.

- Damage or wear: Inspect the float switch for signs of damage and replace if necessary.

Tips for Preventing Future Problems

- Regular maintenance: Follow the manufacturer's recommendations for cleaning, inspection, and calibration.

- Monitor fluid properties: Adjust the float switch settings or replace it if fluid properties change significantly.

- Upgrade to newer models: Consider upgrading to more advanced float switches if your current model becomes outdated or incompatible with new equipment.

YYDS Water Equipment&Supplie

You May Also Like

220V Water Booster Pump Electronic Automatic Booster Water Pump Home Shower Washing Machine Electric Water Pump Jet Booster Pump Faucet Water Pipe Booster

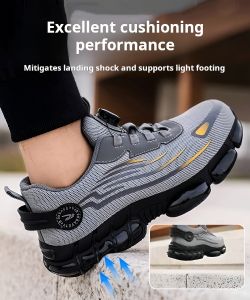

Puncture-proof Shoes Strong Abrasion Resistance New Experience Safety Shoes Soft and Cushioning

HB 60ml Shoe Glue Shoe Repair Adhesive Waterproof and Colorless Adhesive 1Pc

Steel Pin Wall Fixing Tool: A Comprehensive Guide

Ergonomic Handle Cup Lid Brush Multipurpose Lid Cleaning Tool for Kitchen Utensils Protein Shakers Dishware Cleaner

JLD Electric Jigsaw Woodworking PVC Metal Cutting Saw 0° ± 45° Bevel Cuts Limited Time Deal

HB Creative Multifunctional Cleaning Brush Can Be Connected To Mineral Water Bottle Crevice Brush

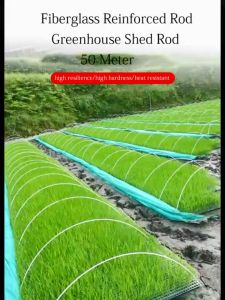

(3 Days Delivery) 50pcs Fiberglass Rod 50x100cm Solid Fiberglass / Fiberglass Rod / Glass Rod / Diy Various Support Rods Diameter 6mm

50 Years Rust-Free: XGJ Anti-Rust Paint for Metal

Sanding Disc Set: 10Pcs 40-7000 4inch Grinding Sand Disc Sander Polishing Tool Grit Flocking Velcro Sandpaper

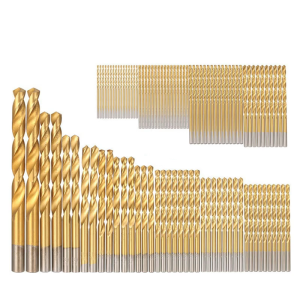

99Pcs Metal Drill Professional Twist Shank Ground Twist Drill Bit for Metal Stainless and Iron Plastic Woodworking