280/480Pcs/Boxed Insulation Terminal Wire Connector Whit Wire Cable Heat Shrink Tube Crimp Terminal

280/480Pcs/Boxed Insulation Terminal Wire Connector Whit Wire Cable Heat Shrink Tube Crimp Terminal

Crimping terminals play a crucial role in the world of electrical connections, providing reliable and secure connections between wires and other components. This article will delve into the intricacies of crimping terminals, insulation terminal wire connectors, and the tools used to make these connections. By the end of this piece, you'll have a comprehensive understanding of the importance of quality crimping terminals and how to use them effectively.

Understanding Crimping Terminals

What is a Crimping Terminal?

A crimping terminal is a small metal component used to connect wires and cables securely. They come in various shapes and sizes, each designed for specific applications. Crimping terminals are commonly used in automotive, electronics, telecommunications, and industrial settings.

Types of Crimping Terminals

There are several types of crimping terminals, including:

- Spade terminals: Used for connecting wires to screw terminals or other spade terminals.

- Ring terminals: Designed for connecting wires to screw terminals or other ring terminals.

- Bullet terminals: Used for quick-connect applications, such as connecting battery cables.

- O-ring terminals: Similar to ring terminals, but with an added O-ring for improved grip.

Advantages of Crimping Terminals

Crimping terminals offer several advantages over traditional soldered connections:

- Durability: Crimped connections are less prone to damage from vibration and movement.

- Speed: Crimping terminals can be installed much faster than soldered connections.

- Reliability: Properly crimped connections provide a secure, low-resistance connection.

- Cost-effective: Crimping terminals are generally less expensive than soldered connections.

Insulation Terminal Wire Connectors

Whit Wire Cable Connectors

Whit wire cable connectors are insulated crimping terminals designed to protect the connection point from environmental factors such as moisture, dust, and corrosion. They are available in various colors, allowing for easy identification of different wire gauges and applications.

Heat Shrink Tube Crimp Terminal

Heat shrink tube crimp terminals provide an additional layer of protection by encasing the connection point in a heat-shrinkable tube. When heated, the tube shrinks around the terminal, creating a watertight seal. This type of terminal is ideal for outdoor applications or areas exposed to harsh environmental conditions.

Applications of Insulation Terminal Wire Connectors

Insulation terminal wire connectors are widely used in various industries, including:

- Automotive: Connecting wires and cables within vehicles.

- Electronics: Building circuits and connecting components in electronic devices.

- Telecommunications: Connecting cables in communication systems.

- Industrial: Connecting wires and cables in industrial machinery and equipment.

Using Crimping Tools for Wire Connections

How to Choose the Right Crimping Tool

Choosing the right crimping tool depends on the type of terminal being used and the gauge of the wire. Some factors to consider when selecting a crimping tool include:

- Terminal compatibility: Ensure the tool is compatible with the specific terminal being used.

- Wire gauge range: Choose a tool that can accommodate the wire gauge being used.

- Tool type: Decide whether to use a manual or hydraulic crimping tool.

Step-by-Step Guide to Crimping

- Strip the insulation from the end of the wire, exposing the desired length of bare wire.

- Insert the stripped wire into the terminal, ensuring it is fully seated.

- Place the terminal and wire into the crimping tool, aligning it with the appropriate die.

- Squeeze the handles of the crimping tool firmly, applying even pressure to create a secure connection.

- Remove the terminal and wire from the crimping tool, inspecting the connection for proper crimping.

Tips for Proper Crimping Techniques

- Use the correct terminal size: Ensure the terminal is compatible with the wire gauge being used.

- Avoid over-crimping: Over-crimping can damage the terminal and wire, leading to poor connections.

- Inspect connections: Regularly check crimped connections for signs of wear or damage.

Troubleshooting Common Issues

Loose Connections

Loose connections can occur due to improper crimping techniques or using the wrong terminal size. To prevent loose connections:

- Ensure proper crimping technique is used.

- Use the correct terminal size for the wire gauge being used.

- Inspect connections regularly for signs of wear or damage.

Overheating and Damage

Overheating and damage can occur if the connection is not secure or if the wire gauge is too small for the current load. To prevent overheating and damage:

- Use the correct wire gauge for the current load.

- Ensure proper crimping technique is used.

- Inspect connections regularly for signs of wear or damage.

Preventing Crimping Errors

To prevent crimping errors:

- Use the correct crimping tool for the terminal being used.

- Follow proper crimping techniques.

- Inspect connections regularly for signs of wear or damage.

Conclusion

In conclusion, crimping terminals play a vital role in ensuring reliable and secure electrical connections. By understanding the different types of crimping terminals, their advantages, and how to properly use crimping tools, you can create high-quality connections that last. Remember to choose the right terminal size, use proper crimping techniques, and inspect connections regularly to avoid common issues such as loose connections, overheating, and damage. Investing in quality crimping terminals and tools is essential for any professional working with electrical connections.

Final Thoughts

Quality crimping terminals and proper crimping techniques are essential for creating reliable and secure electrical connections. By following the guidelines outlined in this article, you can ensure your connections are strong, durable, and long-lasting. Don't forget to invest in quality crimping tools and terminals to achieve the best results.*

BIANCO

You May Also Like

Energy-Saving Shower Head for Hair Salon Wash Station Boosting Water Pressure Plastic Material Single Handle Installation

【E-WOITD】 100PCS Plastic Wire Cable Zip Tie Screw Fixing Mount Base Holder

X7 Violent Blower 500g Blowing Force 40mm Brushless Motor X7 Turbo Fan With 4 Wind Nozzles Air Duster For PC Keyboard Cleaning

Small Travel Limit Switch 3 Foot Micro Switch LXW5/Z-15GW22-B/GQ21/GD Brand Zhongma Electronic Components Market

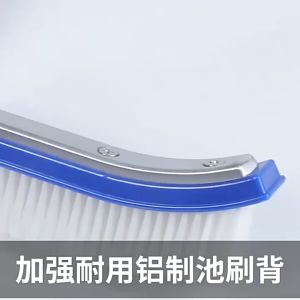

18inch Aluminum Swimming Pool Brush Head For Floor Wall Cleaning Tool Pool Broom With Nylon Bristles

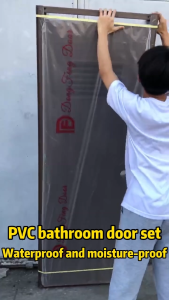

Complete PVC Door Set with Frame Stops Mold & Water Damage Easy to Assemble Upgrade Your Bathroom

15-20mm Glass Clamp 304 Stainless Steel Stair Side Signage Bolt for wood Glass Clamp for Concrete

Ceiling Mounted Microwave Sensors Switches Detectors Automatic Induction Sensors Adjustable Embedded Human Motions Detectors

1HP/1.5HP 220V Stainless Head Jet Booster Water Pump Automatic Jetmatic Pump Self Priming Pump Self Priming Booster Pump

6 Layer Faucet Water Purifier Activated Carbon Kitchen Filter Splash Proof Easy Install Filtration System Clean Drinking

BESTON CLC-50 MVP: The Ultimate USB-C Rechargeable Battery